HVAC in the 21st Century

May 13, 2016 | By Ian McTeer

With the prime HVAC sales season starting in earnest now, it is important to remember that air conditioning contractors must be committed to providing the best possible comfort along with the most efficient cooling systems. But here is the thing: a great deal of Canada’s housing stock built in the last 50 years cannot be cooled efficiently using a conventional furnace and split system air conditioner.

Why is that?

Equipment manufacturers have done an excellent job developing split system cooling units that achieve well over 20 SEER today. But these systems depend on proper airflow and many “stick built” wood frame brick veneer houses do not have proper air distribution systems capable of accommodating modern AC equipment.

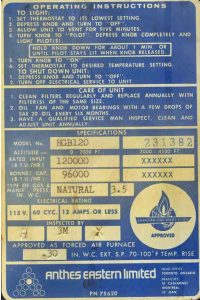

The rating plate shown in Figure 1 came from a gas furnace typical of those used in residential new construction in the early 1970s. This unit is rated at 80 per cent AFUE, however, test methods developed years later proved these belt-driven draft hood equipped models delivered much lower AFUEs, maybe 65 per cent or less. Notice the maximum ESP is 0.30″ w.c. The blower cannot be upgraded to 0.50” w.c.

The rating plate shown in Figure 1 came from a gas furnace typical of those used in residential new construction in the early 1970s. This unit is rated at 80 per cent AFUE, however, test methods developed years later proved these belt-driven draft hood equipped models delivered much lower AFUEs, maybe 65 per cent or less. Notice the maximum ESP is 0.30″ w.c. The blower cannot be upgraded to 0.50” w.c.

Since residential cooling was not common then, no provision for higher static operation was thought to be necessary by the manufacturer. At a maximum of 100F temperature rise, ductwork that could accommodate approximately 900 cfm of air would have likely been installed.

LET ME GUESS…

I suspect the building heated by the original 120K Btuh unit is on its third furnace by now. It was likely replaced by a 100K mid-efficiency in the early 2000s and then by a 90+ per cent AFUE model a few years ago. I guess it is an 80K Btuh unit now because the house has tighter doors, windows and upgraded attic insulation.

That is how the “box movers” sell a furnace – look at the output and sell the next size down is one popular method. The 80K, 95 per cent AFUE models I was associated with required a minimum of 1100 cfm of air in the heating mode to work properly, a 900 cfm distribution system just won’t do. The secret of high efficiency is airflow. Apart from a secondary condensing heat exchanger, modern gas furnaces need to move about 40 per cent more air to stay within the temperature rise range. A 1970s duct system is not a proper match for today’s HVAC equipment’s capabilities.

What about the cooling system? Like so many wood frame houses built across Canada since the 1970s, complaints about decent HVAC on the second floor (especially the master bedroom) never seem to go away. Running small round pipe “lines” as the HVAC TV guys like to call them, that are sometimes hundreds of equivalent feet long connected to convoluted trunk ducts is the reason why the second floor is 10F warmer than the basement where you can “hang meat.”

Non-ducted return air through wooden studs and joist spaces is often full of pipes, wires and joist bracing. The rough wood surface of stud/joist spaces is not conducive to air flow, especially from the second floor. In many cases, the unsealed return air duct and poorly installed joist space block ends are where the majority of return air can “leak” into the system.”

Tips to remember going into this cooling season:

• Sell only AHRI matched equipment.

• Be sure your sales staff knows how to sell VRF multi splits and small duct high velocity products.

• Renovate elderly duct systems whenever necessary, otherwise abandon them in favour of superior modern technology that will deliver the promised efficiency.

• Train your sales staff, installers and technicians including manufacturers’ product knowledge and your own in-house training focusing on HVAC basics and company policy.

• Use accurate test tools, recalibrate as necessary.

• Carefully follow the manufacturer’s installation instructions.

• Commission every new system, take important start-up data and record it for posterity, “blueprint” the job. Take a thermal image of new equipment in operation.

• Sell the end user the best air filter the system can stand.

• Sell the end user a maintenance contract.

• Keep your vehicles in good shape: tire pressures, wheel alignment, driving at the speed limit all help to minimize CO2 pollution.

• Be an HVAC industry champion, we can make the world a better place.MODERN TECHNOLOGY TO THE RESCUE

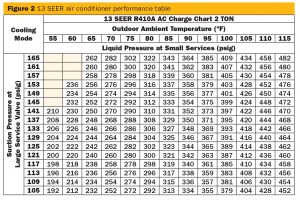

In an effort to provide comfort and efficiency, today’s HVAC contractor needs to carefully examine older brick veneer homes. Contractors need to find out if the second floor heats and cools properly, if the system is noisy, is the basement freezing cold, and whether or not a previous system replacement improved the HVAC or made it worse.Figure 2 is a 13 SEER air conditioner performance table. For example, if the air entering the outdoor coil is 85F, and a gauge attached to the suction port reads 133 psig, then the head pressure should be 327 psig. Typically there is a +/- 10 psig variance on the head pressure, but be sure to check the manufacturer’s specifications for variances. Use the manufacturer’s tables, when available, as a guide to proofing the system.

If your technician cannot get the proper numbers using accurate tools and with the knowledge that the refrigeration side is OK, then airflow has to be the issue. If the customer tells you the air handling system is second rate or worse (confirmed by your airflow testing), then do not recommend a conventional “A” coil, split system replacement. As I see it, there are two alternatives.

If your intention is to completely renovate the duct system to modern standards providing ducted return air and a supply side trunk to the second floor, then continue to use a gas furnace and split AC system.

Abandon the forced warm air system in favour of something else.SOMETHING ELSE

Alternative one could be an answer if the homeowner intends to completely renovate the house (complete gut), otherwise such a duct renovation will be too expensive for the average consumer. Consider abandoning the “box in the basement” for multi zone ductless inverter units made by Panasonic, Mitsubishi, Daiken and others. This equipment provides very high SEER operation, better than 10 HSPF including full capacity heating down to 0F or lower. It eliminates the second floor issue and has a variety of air handlers from ceiling cassettes, wall mounted units, concealed duct, slim duct, floor mounted, and even conventional air handlers when necessary.The second alternative is to utilize one (or more) small duct, high velocity air handler(s) with an inverter drive outdoor unit made by Unico, SpacePak, and several others. With a hot water coil option installed in the air handler, the unit could be matched with a condensing boiler thus providing space heat and domestic hot water too. A conventional furnace in the basement may produce 97 per cent AFUE in the lab, but delivering that efficiency to the homeowner requires a professional system assessment.

The key is to remember that our industry should be providing comfort and efficiency, not just boxes connected to a second rate air handling system. As you approach this selling season be sure your sales staff is ready to specify modern equipment and your service staff is ready to install and to service it.

Ian McTeer is an HVAC consultant with 35 years experience in the industry. He was most recently a field rep for Trane Canada DSO. McTeer is a refrigeration mechanic and Class 1 Gas technician.

HOW I SEE IT

In these days of indigestion it is oftentimes a question

As to what to eat and what to leave alone.

Every microbe and bacillus has a different way to kill us

And in time they all will claim us for their own.

For there are germs of every kind in every food that you can find In the market or upon the bill of fare.

Drinking water’s just as risky as the so-called “deadly” whiskey

And it’s often a mistake to breathe the air.

This is the first verse from a song thought to be written in the late 1800s (more recently quoted by Nucky Thompson in a Boardwalk Empire episode).

In the early 21st century, life in Canada is much safer and decidedly more comfortable. But worries about bacterial contamination; poor water quality; and air pollution have not been left completely behind. Climate change caused by humans polluting the atmosphere with too much CO2 makes the headlines almost every day. I am aware that our planet earth is a very dynamic place, but when it comes to anthropomorphic climate change, I have taken an attitude of uncertain indifference.

I am not denying the evidence, but I am very skeptical that some of the efforts aimed at reducing CO2 pollution are poorly focused, too politically motivated and often

futile. Reduction in energy use requires patience because a nation’s infrastructure is slow to change.

Environmentalist Justin Gillis writing in the New York Times said, “Perhaps the biggest single thing individuals can do on their own is to take fewer airplane trips; just one or two fewer plane rides per year can save as much in emissions as all the other actions combined.”

On a recent edition of CBC’s The National, Peter Mansbridge told viewers that flying from St. John’s, NL to Victoria, BC (with a Toronto stopover) generates one ton of CO2 per passenger. I also learned that commercial aviation accounts for about two per cent of human generated CO2. Despite the fact that commercial aircraft emit close to 70 per cent less CO2 than jet airliners flying in the 1960s, emissions have steadily increased thanks to the popularity of air travel.

GROUND GAS GUZZLING MILITARY AIRCRAFT

Call me naïve, but will there ever be a time for demanding the immediate parking of all military aircraft unless acting in a lifesaving role? Now that we know trips to visit grandma are very harmful, military flights require serious scrutiny. Military jets use staggering amounts of fuel: the F/A-18 jet fighters bombing ISIS in Iraq from the aircraft carrier Vinson stationed in the northern Persian Gulf burn 5700 gallons on the 900 mile round trip to Baghdad. Each plane requires mid-air refueling three or four times. An F-15 Eagle flying with the afterburner lit goes through fuel at the rate of four gallons per second or 14400 gallons per hour.

A group called Environmentalists Against War (EAW) claims the B-52 long-range bomber uses 86 barrels of fuel per hour. One barrel of oil is equivalent to 42 U.S. gallons or 158.9 liters or 5800 cubic feet of natural gas. One hour’s worth of fuel would keep my neighbour’s oil tank filled for the next five years.

The B-52 is 60 years old and at one time there were 740 such planes in service. Today, the B-52 fleet has been whittled to just 76 planes making up the bulk of the U.S. long-range bomber force. There is always at least one B-52 in the air 24/7, plus a fleet of refueling tankers. EAW further states that the U.S. currently has 300 jets stationed on four carrier groups in the Persian Gulf along with 700 more based in Saudi Arabia. Many other countries, including Russia, Britain, France and China, are flying military jets every hour of every day.

HOW DO YOU KEEP ‘EM DOWN ON THE FARM?

For increasingly greater numbers of people around the world, this is the best time to have ever been alive. Just look at air conditioning; according to a recent article in the Guardian, worldwide demand for electricity to power air conditioning equipment is expected to increase by 33 fold before 2100. The U.S. already consumes as much electricity for air conditioning equipment as the entire continent of Africa uses for all electrical devices. In his book, Losing Our Cool, Stan Cox says that over a period of 15 years, the number of air conditioned homes in the U.S. jumped from 64 million to 100 million; however, Chinese consumers purchased 50 million residential units in 2010 alone.

MORE POWER TO THE PEOPLE

Take a trip to the Independent Electric System Operator (ieso.ca) anytime to see where Ontario’s power is coming from and how much is being consumed. At this writing, Ontario’s current demand is 15851 MW; 62.6 per cent generated by the nuclear plants, 23.3 per cent from hydraulic, 5.2 per cent from natural gas, 8.7 per cent from wind, and a miniscule 35 MW from biofuel.

When the IESO site was first made available to the public, wind power on a good day was typically less than one per cent of the total hourly output. Now, after huge investments and the construction of several large windmill farms, wind accounts for a greater proportion of the hourly output when wind permits.

I am not optimistic that renewable sources like wind, solar and biofuel will ever be able to replace the nukes and natural gas. <>