The value of ice-based energy storage in today’s built environment

June 10, 2016 | By Mark MacCracken

Renison University College was founded in 1959. Details of ice based storage system installed there are below.

Energy storage is all around us, from the phone in your pocket to the vehicle on the street. Some forms of energy storage are suitable for the built environment but it is important to understand that energy should be stored in the form it will be used. Ergo, battery technology should be used for powering electronics and ice-based thermal energy storage for cooling.

Thermal energy storage is mainly used to reduce operating costs but it also has a role in reducing the environmental impact of buildings. Solar and wind are forms of pure energy, while fossil fuels are a form of energy with built-in storage. This storage element is what gives us as energy users control over when we collect energy and when we utilize it. Due to the intermittent nature of solar and wind power, one cannot assume that renewable energy will be available when we need it most, so storage picks up the slack.

What is Ice-based Thermal Energy Storage?

Think of ice-based thermal energy storage as a battery for a building’s air conditioning system. By using ice-based thermal energy storage, a building can shift all or a portion of its cooling needs to off-peak, nighttime hours.

During nighttime, or off-peak hours, water containing ethylene or propylene glycol is cooled by a standard chiller. This solution is circulated inside a heat exchanger within the water filled energy storage tanks and turns 95 per cent of the water to ice. The water surrounding the heat exchanger never leaves the tank.

During the daytime, or on-peak hours, a warmer glycol solution circulates through the ice storage tank’s heat exchanger, melting the ice to deliver the stored cool energy to the building. The cold glycol is delivered at the proper temperature to the cooling coil in an air handler. A fan then blows air over the coils to deliver cooling to the occupant spaces. People feel cool and comfortable and never know ice storage is being used.

Wind power, for example, has expanded rapidly in Canada in recent years and is forecasted to continue its rapid growth. As of December 31, 2014, Canada had more than 5000 wind turbines operating on 225 wind farms for a total installed capacity of almost 10000 megawatts, according to Natural Resources Canada. Wind speed and power production varies by season, as well as from night to day. Wind power was proven to be higher at night than during the day with average power production at 43 per cent of maximum generation capacity on summer days, and at 67 per cent on summer nights.

As a result of this nighttime abundance, utilities in some jurisdictions have gone so far as to give renewable energy to customers for free. Thermal energy storage is affording commercial buildings similar advantages by helping energy managers take advantage of cleaner nighttime energy, increasingly made up of renewable wind generation.

Besides the benefits of advancing renewable energy, building owners and engineers have another means of achieving three main goals: sustainability solutions, flexible chiller plant operation and operation cost savings.

Operation costs savings: daytime versus nighttime energy

If gas was half the price at night, when would you fill up your tank? Considering the price of daytime, on-peak electricity is double that of nighttime (or off-peak electricity), it is a wonder more people are not applying this concept to buildings. It is important to note that, when adjusted to today’s dollars, the price of off-peak electricity is the only fuel type that has not increased in price over the last couple of decades.

For those paying for energy under an hourly pricing structure, this price difference may be expected. However, what many people do not realize is that this differential holds true even for those receiving electricity as part of a fixed price contract. One would think a fixed price means energy users pay the same price no matter when they choose to plug in, but this is not entirely true. In Ontario, for instance, any business that uses over 250000 kWh of electricity per year pays a wholesale market price. Wholesale market prices are dynamic, based on supply and demand of energy and consumption of energy by the local distribution company.

In addition to hourly pricing, businesses must also pay energy companies delivery charges, which cover the cost of transmission and distribution lines and generating capacity. Some of these charges change based on the amount of energy used, but others are based on peak energy usage. For example, very large customers in Ontario (over 5MW) must pay a Global Adjustment Charge. This is calculated based on energy consumption during the five highest hours of total grid demand (kW) during the previous year. These are known as the “5 CPs” or coincident peaks. Avoiding these peaks are crucial to keep energy costs low. Global Adjustment charges cost $400 per peak kW annually. Smaller businesses, 50kW to 5MW, pay wholesale prices and a variable Global Adjustment kWh energy charge based on the amount of energy consumed. There is also a demand charge, which varies from $6.00 to $10.00/kW. Demand charges are significant because left unchecked they can make up the largest portion of the utility bill. They are based on a building’s highest electricity peak, normally driven by air conditioning.

With all this in mind, the strategy becomes obvious – install technology that allows one to buy at night when prices are low and use energy storage during the day when prices are high. If on a fixed contract, negotiate using the load profile as leverage (the flatter the better) and switch to hourly pricing to take advantage of off-peak rates. If the building does not have an interval meter, a weighted wholesale price may be an option.

Lastly, look out for incentives. While not necessary to save dramatically on cooling costs, utilities offer grid wide programs to push businesses to lower their peak demand in order to avoid building more infrastructure. Currently, thermal energy storage systems may qualify for $800/kW in Ontario.

Flexible chiller plant operation

Taking advantage of different rates and pricing structures is easy to do with a thermal energy storage system because it gives an energy manager many operational choices. For example, on a hot summer day, a chiller and thermal storage tanks may work together in tandem to provide cooling. When rates skyrocket and a preset demand setpoint is reached or if chiller maintenance is required, the chillers may be turned off and the building may run off of thermal storage alone, reducing peak demand and thereby reducing cooling costs dramatically. During cooler weather when air-conditioning is still needed, one may only use a chiller at night to charge the storage tanks then simply discharge the thermal storage tanks during the day. Every building and/or campus is different. After considering occupancy rates, outside weather and utility rates, a building manager can decide what schedule works best. Today’s controls even allow for remote access from a phone or tablet for greater flexible operation of the thermal storage plant.

Sustainable solutions

According to a report recently commissioned by the Canada Green Building Council (CaGBC), the country’s green building industry is growing. A key driver is the demand for builders and designers who can deliver green buildings and an overarching desire by companies to make sustainability part of core business practices. As evidence of this trend, we can look at LEED buildings, for which thermal energy storage can earn points in the Energy & Atmosphere section. There were 31 LEED-certified buildings in Canada in 2005 and more than 2500 in 2015. Thermal energy storage is a key component to consider as building owners look to invest in more sustainable green buildings.

System Implementation

There are two specific points in a building’s lifecycle when ice-based energy storage should be considered: during construction and when a chiller needs replacing. When undergoing a new construction project, the cost of installing a thermal energy storage system is comparable to a traditional system.

While new construction is a prime opportunity for energy storage, retrofit building projects can also realize benefits. For example, an ice-based energy storage system allows a building to downsize to smaller, more efficient, less expensive HVAC equipment. With energy storage in place, the chiller and its ancillary support equipment do not need to carry the full burden of cooling the building at expensive peak periods. This benefit is also felt by utilities. If the connected load is smaller because of storage, so is the grid’s load.

Energy storage can also be used during expansion projects. Adding more square footage means more cooling will be required. Instead of purchasing a bigger chiller, a thermal energy storage system may be able to meet the additional cooling load of the additional square footage. If a building already has a thermal storage system in place, in some cases, simply adding more tanks could compensate for the increased demand.

Maintenance and Operation

Due to modern day advancement in controls and new pump packages, thermal energy storage systems are simpler than ever. Operating the system is straightforward and operator usability has greatly improved.

For an ice-based system maintenance is minimal. The water level of the tanks needs to be checked once a year to ensure that it is filled to the proper level. At that time, the concentration and health of the heat transfer fluid should be checked and treated, if necessary. Since there are no moving parts in the storage tanks, there is virtually no more “wear and tear” than a non-storage system. In addition to requiring minimal upkeep, the tanks are known to last for decades – with many outliving the very buildings in which they were installed.

All-in-all, there are significant benefits to energy storage and Canadian engineers and businesses are in a prime position to take advantage. Not only does thermal energy storage advance the exciting potential of renewable energy but it also offers the ability to dramatically reduce cooling costs and provide more flexible operation of the chiller plant.

Mark MacCracken is CEO of Calmac Corp. MacCracken holds a BS in mechanical engineering, has three U.S. Patents and is a LEED fellow. www.calmac.com

References

http://www.nrcan.gc.ca/energy/renewable-electricity/7295

https://www.llnl.gov/news/power-generation-blowing-wind

http://www.ieso.ca/Pages/Power-Data/default.aspx#price

http://www.ieso.ca/Pages/Ontario’s-Power-System/Electricity-Pricing-in-Ontario/default.aspx

System exceeds expectations

The Region of Waterloo’s first building cooling system with thermal storage is located at Renison University College. It was engineered in partnership with WalterFedy in Kitchener, ON and Trane. The college, which operates year round, spans across six acres of land and provides offices, classrooms, libraries, cafeterias and residences to thousands of students.

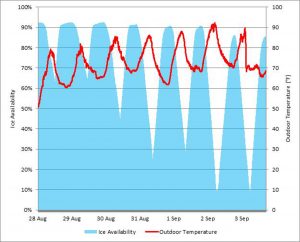

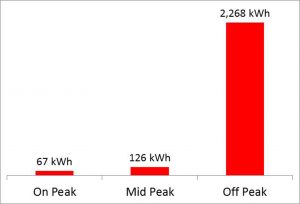

Figure 2 On peak – mid peak – off peak Figures 1 and 2 show the performance of the system for a one-week period from August 28 to September 4, 2015. During this week, outdoor temperatures exceeded 90F and the system still shifted 97 per cent of electrical consumption to off-peak hours.

In the summer of 2015, the college underwent a 35,000 ft2 (3252 sq. meter) expansion, resulting in the construction of a new three-storey academic building. Considering that Ontario has some of the most expensive electricity in North America, it was important to implement a HVAC design that could minimize electricity charges and peak demand charges within the building. Rather than add a 90-ton chiller to cool the additional space, the design team downsized to a 52-ton chiller paired with energy storage tanks. By installing energy storage, electricity used for cooling is shifted to off-peak hours.

The chiller generates ice, which is stored overnight in the energy storage tanks when energy prices are at their lowest. The next day the ice is melted and used to cool a heat transfer fluid, which cools the air that is pumped throughout the building to keep occupants comfortable. By selecting the smaller chiller, WalterFedy was able to save more than enough to pay for storage tanks, making the incremental cost of using energy storage essentially zero.

Part of the funding for the expansion was granted from Ontario’s Save on Energy program and, therefore, meant that savings needed to be tracked and verified. WalterFedy analyzed the performance of the technology during the month of August 2015 – a time when outdoor temperatures exceeded design conditions. Despite that, savings were greater than what had been predicted prior to installing the system with 97 per cent of the cooling system’s electricity use shifted to the off-peak hours of 7 p.m. to 7 a.m. Peak electrical demand for a conventional air-cooled chiller was predicted to be 95 kW and the system did not exceed 6.4 kW during the on-peak hours of 11 a.m. to 5 p.m. for the month. This is a peak demand reduction of 88.6 kW.