Insights on refrigerant flammability and safety

May 16, 2017 | By Spencer Fuller

After the Montreal Protocol began the phase-out of chlorofluorocarbon (CFC) refrigerants in 1987, the HVAC industry began to test alternative refrigerants. Since then, the industry’s primary concern has been “safety first.” This does not mean just environmental safety, but also safety for people who handle refrigerants or who are near equipment containing refrigerant.

After the Montreal Protocol began the phase-out of chlorofluorocarbon (CFC) refrigerants in 1987, the HVAC industry began to test alternative refrigerants. Since then, the industry’s primary concern has been “safety first.” This does not mean just environmental safety, but also safety for people who handle refrigerants or who are near equipment containing refrigerant.

Currently, the HVAC/R industry is tackling the third paradigm shift in refrigerant chemistries – the first, went from CFCs to hydrochlorofluorocarbons (HCFCs), the second, from HCFCs to hydrofluorcarbons (HFCs), and now the third, from HFCs to hydrofluoroolefins (HFOs), HFO blends, and other low-GWP formulations. Each change in chemistry has reduced the atmospheric lifetime of the refrigerant molecule in question by an order of magnitude. For example, the atmospheric lifetime for CFC-12 is 100 years, HFC-134a, 13 years, and HFO-1234yf, 10 days.

Refrigerant molecules that rapidly degrade have less impact on the environment. But rapid decomposition in the atmosphere is another way of saying that the refrigerant oxidizes quickly and, therefore, is more likely to be flammable under certain conditions. Moreover, more reactive chemicals tend to be more toxic. As a result, the industry is committed to thoroughly investigating the safety of today’s fourth-generation refrigerants.

SAFETY IS WORTH THE INVESTMENT

HVAC/R equipment manufacturers contribute to industry research organizations such as the Air-Conditioning, Heating, and Refrigeration Institute (AHRI) and the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE). But we also financially contributed to dedicated research into how to safely apply the new class of refrigerants.

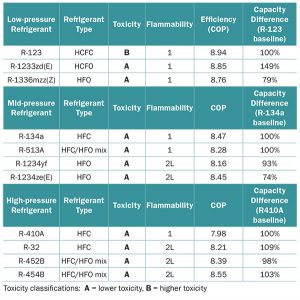

Making this transition is not without its challenges. First, several of the fourth-generation refrigerants are mildly flammable, and a subset of those has a higher toxicity rating (see Figure 1).

ASHRAE Standard 34 classifies refrigerant flammability and toxicity. Letters A and B designate lower and higher toxicity. A number system denotes the level of flammability, with 1 for none, 2 for low and 3 for higher flammability. In practice, the flammability and toxicity and classifications are combined to indicate the general safety of the refrigerant. For example, HFC-134a is classified A1.

For third-generation transitional refrigerants, the optional classification of 2L was created to indicate slight flammability. Compared to Class 2, Class 2L substances burn slower and are more difficult to ignite and sustain a flame.

Underwriters Laboratory listing UL 1995 (issued jointly by Canadian Standards Association) pertains to HVACR applications. It is being revised in accord with international standard IEC 60335-2-40 to include A2L refrigerants.

ENSURING SAFETY TAKES TIME

Indeed, research, certifications, regulation and implementation take time. It is important to be right, not quick, to ensure this transition is made safely.

The use of A2L refrigerants affects equipment standards, building and fire codes, construction practices, manufacturing processes, material handling and life safety procedures – all of which must be updated to ensure refrigerants can be used safely. Safety remains the primary objective and cannot be compromised.

Revising the building code takes time. For example, the next round of the International Building Code that could include A2L refrigerants begins in 2018 for codes implemented in 2021. Keep in mind that the mandate to adopt HFC-free refrigerants in chillers occurs by January 1, 2025.

Throughout this transition, it is important to note that equipment owners are not required to switch to a new refrigerant today. At this time, HFCs are not on an accelerated phase-out schedule, making them a safe, economical option while alternatives are being adopted.

Manufacturers, aware of this transition process, are evaluating new refrigerants and other technologies to advance performance, cost and safety of their products. Most manufacturers have been monitoring, testing and prototyping many of these refrigerant alternatives for years.

SAFE AND SMART DECISIONS

For a R-134a centrifugal and screw chiller platform, for example, medium pressure R-513A refrigerant, serves as a good alternative in terms of safety (A1, non-flammable, low toxicity), performance and cost. Other options were less attractive due to flammability, toxicity and/or a greater loss in performance (capacity, efficiency or both) (see Figure 1), and considerably higher installed cost.

For scroll chiller platforms, several potential alternatives have been identified. For outdoor chillers, A2L flammability risks can be addressed. However, flammability presents a greater challenge for indoor equipment, and for direct systems like rooftops, splits, VRF and unitary equipment.

In many cases, the new refrigerants under consideration are not currently available in large quantities. In fact, most refrigerant producers are forecasting the bulk of their production will not come online until 2018 at the earliest. In the meantime, these new refrigerants, limited in their availability, come with significant price premiums when compared to HFCs.

This reinforces the commitment from manufacturers — and the commitment from the industry – to continue to press for development and regulatory timetables that ensure end users have safe refrigerant options well before regulations are implemented.

HITTING TIGHT TIMETABLES

Regarding timetables, a letter submitted by the Natural Resources Defense Council (NRDC) and Air-Conditioning, Heating, and Refrigeration Institute (AHRI) to the U.S. EPA in February 2016 supported January 1, 2025 as the effective date to adopt HFC-free refrigerants. While this date will be challenging for chiller manufacturers with large existing product portfolios, the experience gained in previous transitions should make a smooth transition possible so long as building and fire codes are updated.

This is the third major paradigm shift for refrigerants. Now with HFO and other alternatives on deck, the HVAC/R industry, chemical manufacturers, and standard and code bodies have the experience to handle the transition. The goal is to ensure customer safety and improve system efficiency, but the end date of 2025 means everything will be moving faster this time.

Spencer Fuller is regional sales manager, chiller solutions, building technologies and solutions with Johnson Controls.