Benefits and Pointers on Buffer Tanks

July 2, 2021 | By Logan Caswell

Both Goldie and Pelligrino broke down how the buffer tank gives the boiler, or other heat source such as a heat pump, a mass to heat up and reduce the event of short cycling.

In this 30 Mechanical Minutes session HPAC Magazine sits down with Steve Goldie, HPAC writer and hydronics specialist at Next Supply, and Nick Pellegrino, technical sales specialist with Thermo 2000, to discuss applications, benefits and pointers on the best use of buffer tanks.

“I’ve been a proponent and a big fan of buffer tanks for many years now,” says Goldie. A buffer tank makes a boiler happy, and who doesn’t want a happy boiler?”

Both Goldie and Pelligrino broke down how the buffer tank gives the boiler, or other heat source such as a heat pump, a mass to heat up and reduce the event of short cycling. Both compare the buffer tank to a battery that takes in the thermal charge from the heating appliance, and as energy gets consumed the appliance will get called upon to re-charge the tank. As opposed to systems where a boiler is designed to switch on and off in direct response to loads; a buffer tank separates the boiler from the call for heat from the loads, allowing it to run longer and get into its full state efficiency while heating up the buffer tank, and it stays off longer between cycles.

Two-pipe, four-pipe, or more…

As for buffer tank set up, Pellegrino describes the two-pipe system as a newer way of doing things, but both speakers prefer the four-pipe set up. One advantage of a two-pipe connection is that it’s not hydraulically decoupling the boiler (or heating appliance) from the demand side, so one pump can circulate, notes Goldie, but he also points out, “You’re also now sacrificing all the potential benefits of a buffer tank.”

With four-pipe connections, there is an inlet and an outlet creating a loop on the boiler side dumping energy into the tank, and then two connections on the other side drawing that energy out to the load and returning cold water to the tank.

As Goldie explains, this set-up allows the tank to stratify, allowing the system to take advantage of the different temperatures in a tank. “When you go to multiple connections there’s all sorts of great things we can do with buffer tanks,” he says.

Sizing your tank

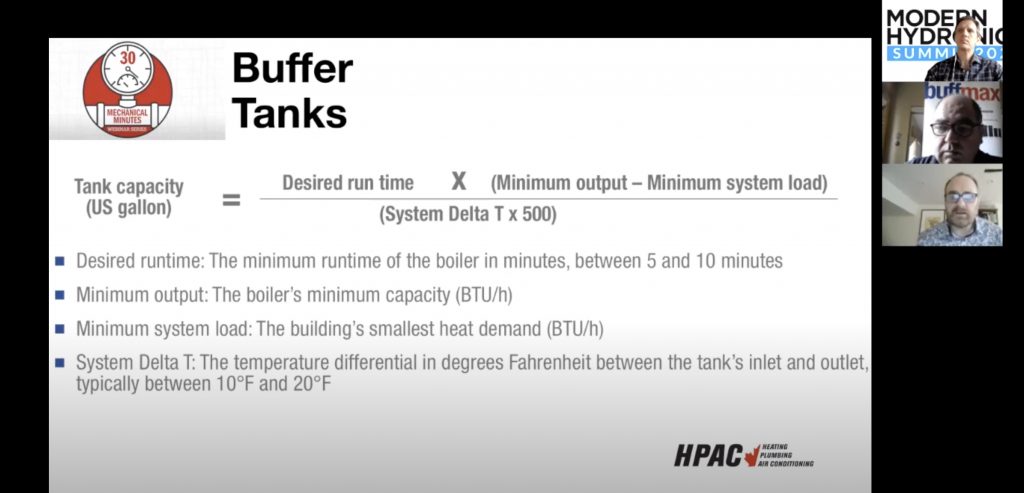

The panelists agree that it’s never a bad thing to oversize a buffer tank, but there is a sizing formula designers can follow using desired minimum run time for the heating appliance (Goldie suggests 10 minutes), the minimum thermal output of the heating appliance, the smallest load on the system, and also the Delta T between the tank’s inlet and outlet temps (see photo above).

How do you justify the tank?

To get the benefits of a buffer tank there is an added cost. “You’ve got to educate the consumer, whether it’s the end user or the general contractor, and make sure they understand the implications,” says Goldie. “If we want the system to work as well as current technology can, then a buffer tank needs to be a part of that system.”

A buffer tank offers other benefits: it acts as a hydraulic separator, it has air venting and it can serve as a chiller unit for cooling. But Pellegrino advises: “Remember to properly insulate the tank. Condensation is the enemy of a chilled water system.”

Final comments

For Pellegrino, the buffer tank is all about efficiency, and Goldie re-emphasizes his fondness for buffer tanks: “I don’t care if it’s condensing or not condensing, buffering makes every boiler better— period.”