Beyond the furnace tune-up

October 26, 2016 | By Ian McTeer

A furnace tune-up is really a comprehensive maintenance job. Contractors know that it is essential to maintain a long-term relationship with every customer by providing timely preventive maintenance (PM) at least once per year. It is better to work with a preferred brand: parts availability, warranty claims and technician training are known quantities allowing the contractor to offer better service. Maintenance becomes problematic when end-users do not subscribe to a PM program.

When it comes to safety, every properly trained technician knows to inspect important things like chimneys, vents, flue dampers, gas piping, limit controls and other devices that the manufacturer deems necessary. It is the stuff one never expects that can lead to very uncomfortable situations with the customer. “Le client n’a jamais tort” (the customer is never wrong) proclaimed César Ritz, a famous hotelier. Sales people seem to warmly embrace such ideas, however, technicians know that some customers have unrealistic expectations and will otherwise abuse or neglect a furnace so that a warranty or extended warranty might become void.

Sometimes it is a safety issue related to a homeowner’s DIYing. Once on a no heat call, I noticed the mid-efficient furnace was vented with the long-since banned HTTP plastic venting material. The customer had completely finished his basement having moved the furnace about 10 feet away from the outside wall. Since he could not buy more HTTP piping material, he had Macgyvered a coupling to an additional length of three-inch stainless steel pipe that continued the vent to a termination point outside.

The HTTP was in contact with wooden joists and studs; the original specification required nine inches of clearance to combustible material. I turned him off and it was only after I asked him to consider the safety of his family that he calmed down and pulled out some electric space heaters.

A word of advice to technicians – do not end up owning someone’s dangerous incompetence. Keep a supply of red tags handy and be sure to carefully explain your intent to tag an appliance citing violations of gas code or manufacturer’s installation instructions.

From a mechanical perspective, a PM visit to a modern high efficiency gas furnace is considerably more complex than the standing pilot models of yesterday. I would argue that draft induced furnaces are safer than their draft hood equipped brethren simply because a cracked heat exchanger is, realistically, no longer a potential killer. Since a draft induced heat exchanger operates under a negative pressure, there is no risk of flue products leaking into the airstream during operation. Indeed, a draft induced furnace could operate for an entire heating season before a heat exchanger crack prevents the pressure switch contacts from closing at the start of the cycle or opening during the cycle.

It is the small things that must be checked on a PM, such as the flame rod, condensate system, electrical connections, gas pressure, total amps, air filter, cleanliness of major components and vent termination. Some technicians simply replace the flame rod every year, but this act does not guarantee a trouble free heating season without testing the flame signal too. For example, a White-Rodgers ignition system will lock out the combustion process if the flame signal drops below one DC microamp. Even though the flame rod was replaced, how would a technician know if there were other problems in the flame detection system. These might include a control board problem, grounding issue or perhaps the burner crosslighter is partially blocked so that the flame rod is not always completely enveloped by the flame.

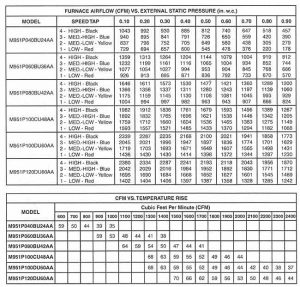

This manufacturer’s blower performance chart shows airflow and temperature rise for several different models. The unit outlined in red has four potential blower speeds and shows the maximum airflow against the rating plate external static pressure of 0.5-inch w.c. The medium low speed delivers 953 cfm, which is the lowest speed this model could ever use for heating. Notice the temperature rise chart shows the measured temperature rise should be 59F at 900 cfm. The maximum temperature rise for this particular model is 60F. There is no temperature rise number for this model associated with an airflow of 800 cfm – it means an air volume less than 900 cfm will eventually damage the heat exchanger. Technicians should be familiar with temperate rise and blower performance charts to ensure proper air volumes will result in heat exchangers standing up to the test of time.

TEMPERATURE RISE

Modern heat exchangers are paper thin compared to yesterday’s “boiler plate” assemblies. Aluminized steel of 18 to 20 gauge thickness is used by many manufacturers because heat is transferred to the airstream rapidly and efficiently, less fuel is consumed in the act of warming up the heat exchanger itself. Clam shell, tubular aluminized and tubular stainless steel designs are commonly used today, but there is one weakness: operation outside of the manufacturers’ designated temperature rise range will lead to premature failure.

The manufacturer’s gas furnace rating plate shows the temperature rise range within which the unit must operate at all times. Drilling down into a particular furnace’s specifications will provide details of expected temperature rise at a given airflow. For example, even though a rating plate indicates a rise range of 40F to 65F, data might show that a specific unit operating at 1000 cfm should have a rise of 60F maximum. A rise measurement of 65F on this unit and subsequent calculation (CFM = Btuh/temperature rise x 1.08) shows the airflow is only 900 cfm means this unit is running outside its rise range and premature failure of the heat exchanger will occur.

DUCT SYSTEM TUNE-UP

Forced air furnaces, whether they are gas, oil or electric, operate outside of their temperature rise ranges almost always because of system-related problems. Other than massive over firing or a failed blower motor, a furnace that cannot get enough air through the return side or cannot get rid of enough heated air through the supply side will continually overheat wasting incredible amounts of fuel in the process. Assuming the furnace and its related air handling components are clean and serviceable, customer complaints about cold rooms, drafts and velocity noise arise solely from inadequate distribution systems.

It may be next to impossible to solve ductwork related problems. But, as an add-on service, a system tune up might be in order. Spend an hour finding out where the air is going and in what quantity. With existing dampers and perhaps a few other dampers installed at appropriate locations in the ductwork, air can be forced to places it has never been.

There are several helpful things to be done above and beyond a typical furnace maintenance call to help improve overall comfort and efficiency. A clean and superbly tuned modern gas furnace resigned to work in a crummy duct system is somewhat analogous to driving a Lamborghini Centenario along the bumpiest road in the county.

Every marketing person knows that it costs more to gain new customers than it does to keep existing customers. Tune them up, keep them happy and comfortable, you will have a customer for life and maybe a referral or two.

Ian McTeer is an HVAC consultant with 35 years experience in the industry. He was most recently a field rep for Trane Canada DSO. McTeer is a refrigeration mechanic and Class 1 Gas technician.

HVAC TUNE UP-WHAT TO WATCH FOR

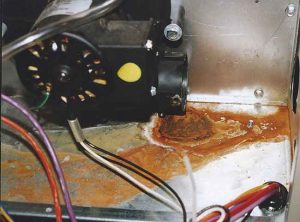

Condensate management: acidic condensate leaks cause property damage. Manufacturers typically want ½-inch PVC (minimum) used as drain piping material as it prevents kinks, is leak resistant and cannot be easily crushed.

Condensate management: acidic condensate leaks cause property damage. Manufacturers typically want ½-inch PVC (minimum) used as drain piping material as it prevents kinks, is leak resistant and cannot be easily crushed.

Burners must be clean. A tiny amount of lint in the cross lighter can cause delayed ignition and/or inadequate flame signal.

Rust on top of the burner caused by flue gas recirculation into the combustion chamber. Incorrect vent termination: tee-wye not allowed, must be straight tee. In this case, a tee is not even necessary.

This 1956 vintage heat exchanger has a large hole that was probably caused by years of flame impingement. This is a serious safety issue.

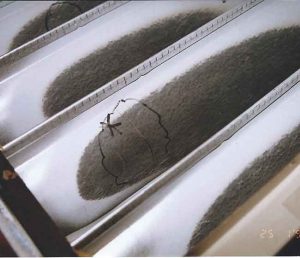

Aluminized steel heat exchanger with several hairline cracks. Cracks caused by inadequate air flow through an undersized evaporator coil.

Cased evaporator coils can sometimes be used as an inspection portal to observe coil cleanliness and heat exchanger condition. Removal of inner panel allows adequate access to important components.

Cased evaporator coils can sometimes be used as an inspection portal to observe coil cleanliness and heat exchanger condition. Removal of inner panel allows adequate access to important components.

Secondary heat exchangers must be clean to guarantee efficient heat transfer.

Blower wheels get dirty and should be checked every PM. Depending on conditions and the type of air filter used, the wheel may have to be cleaned every other year. After any construction work done in a house while the furnace is running, a thorough cleaning should be done once the construction is finished.

Blower wheels get dirty and should be checked every PM. Depending on conditions and the type of air filter used, the wheel may have to be cleaned every other year. After any construction work done in a house while the furnace is running, a thorough cleaning should be done once the construction is finished.

This 80K btuh furnace (using indoor air for combustion) and a 50K water heater were once in a wide-open basement. Subsequent finishing by the homeowner created a room with an air volume of only 2016 cubic feet. Furnace installer’s guide requires outdoor air whenever a confined space has less than 50 cubic feet of volume per 1000 btuh of gas input including that of other gas appliance in the space. A PM or no heat call to this job means the new customer is facing an unexpected expense.

This 80K btuh furnace (using indoor air for combustion) and a 50K water heater were once in a wide-open basement. Subsequent finishing by the homeowner created a room with an air volume of only 2016 cubic feet. Furnace installer’s guide requires outdoor air whenever a confined space has less than 50 cubic feet of volume per 1000 btuh of gas input including that of other gas appliance in the space. A PM or no heat call to this job means the new customer is facing an unexpected expense.

A PM does not include a heating distribution system tune-up. If the customer has specific issues like velocity noise or poor airflow to a particular area, an hour’s worth of investigation could help a bit. In this case, no wonder the register is noisy: 111 cfm at a velocity of 903 fpm through a five-inch pipe is enough to keep anyone awake at night.

A PM does not include a heating distribution system tune-up. If the customer has specific issues like velocity noise or poor airflow to a particular area, an hour’s worth of investigation could help a bit. In this case, no wonder the register is noisy: 111 cfm at a velocity of 903 fpm through a five-inch pipe is enough to keep anyone awake at night.