Considerations for operating hybrid radiant-DOAS systems

March 3, 2020 | By Sanjil Karki

Designing for comfort and efficiency in commercial buildings through optimized controls of a hybrid system.

HVAC system designers do not need to choose between comfort and efficiency in commercial buildings. By integrating a radiant heating/cooling system with a dedicated outdoor air system (DOAS), both of these performance attributes can be optimized. This technology decouples sensible and latent loads, allowing the key variables that optimize comfort and energy efficiency to be independently and precisely controlled.

Radiant heating/cooling has been combined with DOAS at Sheridan College Davis Campus (Brampton, Ont.) Pictured: The three-storey atrium at the Skilled Trades Centre (source: REHAU)

The potential synergy of hybrid radiant-DOAS systems is underutilized. This article discusses three important considerations for designing a sequence of operations that makes the most of this technology.

Radiant system control strategy during shoulder seasons;

A hydronic radiant floor system is controlled by changing either supply water temperature or supply water mass flow rate. Typically, outdoor temperature reset controls are used to modulate the supply water temperature based on outdoor air temperature and control the water flow rate to each room according to setpoint temperature. The average system supply temperature should also be controlled for faster and more consistent operation.

A typical radiant heating system is designed to a handle space load up to 32 Btu/h-ft2 (100 W/m2) with a maximum allowable slab temperature as per ASHRAE Standard 55 of 85F (29.4C). A radiant cooling system can provide a cooling capacity up to 14 Btu/h-ft2 (44 W/m2) with latent loads and supplemental cooling typically provided by a DOAS system. In areas with high direct solar loads, the system’s capacity can significantly increase up to 25 Btu/h-ft2 (79 W/m2), but accounting for this transient capacity is not always advisable from a system sizing standpoint. For comfort, ASHRAE Standard 55 mandates a minimum radiant cooling slab temperature of 66F (18.9C).

During shoulder seasons, between heating and cooling modes, what is the best way to control the radiant system? Research by the Center for the Built Environment (CBE) at the University of California Berkeley reached the following conclusion: If the building has a lot of exposed thermal mass and a well-designed envelope, there are no times of the year when heating is required in the morning and cooling required in the evening. These types of buildings respond more closely to the 24-hr average of the outside air temperature conditions and can coast through shoulder season days on thermal mass.

DOAS supply air temperature control strategy

Radiant systems provide sensible cooling/heating and are typically configured as a hybrid with an air system, which is used for ventilation, dehumidification and supplemental cooling/heating, if needed. Typically, radiant does the heavy lifting to maintain the sensible load, by warming or cooling surfaces in the space. DOAS is primarily focused on latent loads, but can assist with sensible loads on summer and winter design days, depending on the project.

Radiant heating/cooling system being installed in Sheridan College Skilled Trade Center. (source: Klimatrol Environmental Systems Ltd.)

In cooling mode, DOAS dehumidifies and delivers the required amount of outdoor air conditioned to handle the latent load of both the outdoor air and the space. This requires a supply air dew-point lower than the room air dew-point, typically 48-50F (8.9-10C).

DOAS handles the entire latent load and radiant is only responsible for sensible cooling. This decoupling of the space sensible load from the latent load affords precise humidity control regardless of space thermal load. Humidity control problems often associated with part-load operating conditions are manageable and designers can easily prevent condensation in the space, even in humid cities such as Windsor, Ont.

The supply air temperature of the DOAS is an important factor in achieving maximum energy savings. To handle the entire latent load, the supply air must be dehumidified to a dew point that is lower than space, which typically means overcooling the outdoor air. Designers must choose between supplying air at “space neutral” or “cold air” condition straight off the cooling coil.

When “space neutral” air is supplied, the dehumidified air must be reheated to introduce fresh air into space without affecting the thermal loads, thus wasting all the sensible cooling done during dehumidification. When “cold air” is supplied, the air coming from the unit does not require reheating. With the outdoor air handling some of the sensible cooling, annual energy consumption of the local HVAC unit is significantly reduced.

One control strategy that can be implemented is resetting the discharge temperature based on outdoor air. When outdoor air conditions are such that overcooling is likely, the supply air is reheated to a neutral temperature. This can be accomplished using a microprocessor controller such as a direct digital control (DDC) for discharge air control; the DDC controller monitors the ambient temperature and resets the discharge temperature of the outdoor air unit accordingly.

A more advanced approach to this strategy is to implement a building management system (BMS) that can monitor multiple spaces and determine the “critical space.” Once the critical space is determined, the BMS can adjust the reheat capacity of the outdoor air unit to prevent the critical space from being overcooled or overheated.

Another controls strategy for saving energy is to utilize humidistats and dehumidification in critical spaces. If the humidity begins trending up, the humidistat sends a signal to the controller that more dehumidification is needed. The controller then lowers the discharge dew point of the outdoor air unit for further dehumidification. Once the room humidity reaches an acceptable level, the dew point is reset back to normal operation.

Zero-energy-building (ZEB) trends

Beginning with Vancouver, more than a dozen Canadian cities have taken steps toward the ambitious goal of 100% renewable energy. Last year, Berkeley, California became the first American city to ban natural gas infrastructure in new buildings after PG&E, the second-largest U.S. utility and notably, both a gas and electric utility, publicly supported the move. These cities are part of an international trend that will cut natural gas demand through building electrification, swapping out fossil-fuel-powered appliances for electric appliances.

With electrification, engineers are challenged to design HVAC systems that can provide efficient space conditioning without being penalized on utility bills. Heat pumps integrated with hydronic radiant are important components of ZEB design. By extracting heat from a lower temperature source and transferring it to a higher temperature source, modern heat pumps use 66 to 75% less energy than electric resistance heating/cooling appliances.

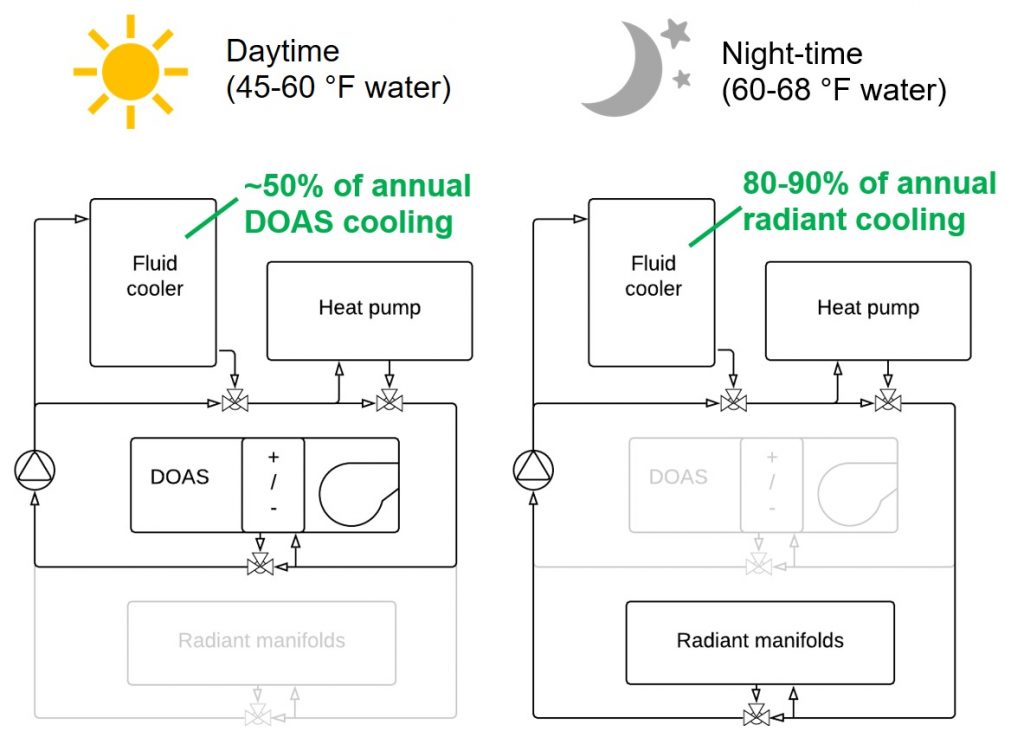

Figure 1: Example of all-electric design concept for high thermal mass radiant systems operating in cooling mode. This strategy leverages thermal mass to significantly reduce heating/cooling demand and utility cost, eliminating fossil fuels and approaching ZEB targets.

CBE’s all-electric design concept (figure 1) uses an air-to-water or ground-source heat pump, a DOAS system, a fluid cooler or closed-circuit cooling tower and a radiant system. At night, the heat pump provides warm or cool water to the radiant slab depending on the season. At the end of each day’s occupied period, the system gets feedback from the previous-day slab temperature and the controller gradually changes the slab setpoint during the next 12 hours. In this way, the controller gradually responds to changes in the zone loads over the course of several days. These designs provide excellent hydronic system energy efficiency while being all-electric.

For example, if the previous day’s outdoor condition is 90F (18.9C), the radiant slab will be in cooling mode. The heat pump will generate 60-68F (15.6-20C) water that will be circulated through the radiant slab during the night, pre-cooling the slab.

As the occupants arrive in the morning, the slab begins absorbing heat from the space and DOAS begins providing ventilation. If the outdoor air needs to be dehumidified, then the heat pump will provide 45-60F (7.2-15.6C) water to the DOAS system. As the day progresses, the radiant slab slowly absorbs heat from the space. If the radiant system is not able to handle all of the cooling load, the DOAS system could then provide supplemental cooling using the chilled water from the same heat pump.

During milder weather, the closed-circuit cooling tower or fluid cooler is used for water-side economizer operation, providing an additional 80-90% savings on the radiant cooling system.

Since the same heat pump is providing warm or cool water to radiant during the night and DOAS during the day, the mechanical plant size is significantly reduced. Another key benefit of this design is shifting the heating and cooling loads from peak to off-peak hours when utility rates and demand charges are lowest. Heat pump water temperature and savings will vary depending upon project location.

By addressing shoulder season variations, DOAS supply air temperature and meeting the market trajectory toward electrification, a well-designed hybrid radiant-DOAS system does not need to compromise comfort and controllability to optimize energy efficiency. From sequence of operations to building specification, these factors allow radiant and air-side systems to each do what they do best, even in ZEB designs.

Sanjil Karki is an engineering sales specialist for the building solutions division of REHAU, responsible for western United States, Alaska and Hawaii. In this role, he educates engineers and commercial contractors on radiant heating and cooling, snow and ice melting, PEX plumbing and geo-exchange systems. Karki serves on the advisory team of “Optimizing Radiant Systems,” an initiative of the Center for the Built Environment (CBE) at the University of California Berkeley.