Cut it Out with the Cut-Out Questions

October 5, 2021 | By Chris DesRoches, P.Eng.

Old ways of thinking about heat pumps are not compatible with a low carbon future.

The term “heat pump” has many misnomers and gets thrown around far too loosely these days as HVAC conversations shift towards sustainability, low carbon emissions and building electrification. It is important to remember that a heat pump can exist in a wide variety of sizes and types to suit endless applications – when designed and implemented properly.

A niche subset of heat pumps that are gaining momentum in the Canadian hydronics market are air-to-water heat pumps, which, aside from electric boilers, are an alternative to traditional fossil-fuel based boilers. Heat pumps sound attractive, so when it comes to hydronic systems, why are they still lurking in the shadows?

Air-to-water heat pumps extract heat from the air outside a building, so the machine’s ability to perform efficiently and provide useful heating is greatly influenced by outside air temperature. Any heat pump will have practical limitations due to the refrigerant being used, and it will eventually shut off when it can no longer effectively provide useful heat to the building. This is commonly referred to as the “low ambient cut-out temperature.”

And when it comes to designing with air-to-water heat pumps, the most critical design consideration the Canadian market is fixated on, and the first question to come up in heat pump conversations with a contractor or engineer is: “So… What about the cut-out temperature?”

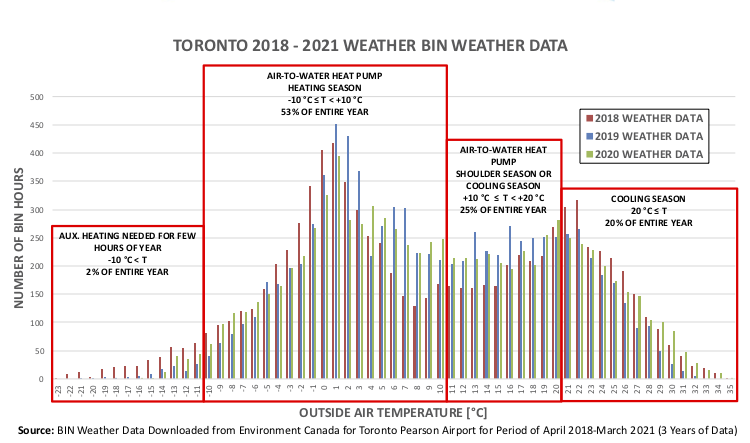

While there have been great strides in improving heat pump performance and pushing the limits to operate in colder temperatures, usually, the design temperature is below the heat pump cut out temperature and can become an obstacle. In these cases, an auxiliary heat source will be required when using air-to-water heat pumps. However it is important to recognize the frequency of time where it is colder than the cut-out temperature for the majority of Canada’s built environment is relatively few hours, typically just a few weeks of the heating season. In favourable climates, such as coastal cities or even Toronto, this can be less than a week of the entire year. When it comes to heat pumps, it’s about using the heat pump when it makes sense to do so.

Primary criteria for designers and building owners when selecting a new mechanical system has traditionally been equipment first installed costs and operating costs. So, it’s no surprise that gas-fired boilers have been the norm in Canadian hydronic systems for decades due to widely available low-cost natural gas, the simplicity of designing with hydronic boilers, not to mention they are relatively inexpensive. Boilers do not have the same design challenges or constraints that air-to-water heat pumps have, so even just a few years ago it was easy for an engineer to explain to a client why they wouldn’t entertain an alternative to a boiler.

Primary criteria for designers and building owners when selecting a new mechanical system has traditionally been equipment first installed costs and operating costs. So, it’s no surprise that gas-fired boilers have been the norm in Canadian hydronic systems for decades due to widely available low-cost natural gas, the simplicity of designing with hydronic boilers, not to mention they are relatively inexpensive. Boilers do not have the same design challenges or constraints that air-to-water heat pumps have, so even just a few years ago it was easy for an engineer to explain to a client why they wouldn’t entertain an alternative to a boiler.

The design criteria are undergoing substantial change as the market shifts towards prioritizing energy efficiency and sustainability. Building and Energy Codes, as well as the metrics used to define what constitutes a “cutting-edge” and sustainable design are becoming more stringent. Limits on Energy Use Intensity (EUI), Thermal Energy Demand Intensity (TEDI), Greenhouse Gas Intensity (GHGI), among other metrics, are being closely scrutinized, and the bar is consistently being raised. While these metrics may be optional and modest today, they will become prerequisites and even more stringent as time moves forward to achieve net-zero in new buildings by 2030.

The Federal carbon tax will also transform the industry towards electric heating solutions, which brings us full circle back to air-to-water heat pumps. By focussing on improving building designs with both active and passive energy reduction measures, we can improve our buildings’ carbon footprint, but will these measures be enough?

Air-to-water heat pumps are one part of a wider solution, and it is clear that heat pumps will become more common on the path to 2030 in hydronic systems.

Do the heat pumps have limitations? Yes, but there are workarounds. In a lot of cases, an auxiliary heat source will be needed, but the days of seeking one size fits all solutions are finished, as it is often not compatible with a low-carbon future.

This should not be viewed as a negative, but rather a benefit by providing buildings with resiliency and redundancy, and the potential for flexible dual-fuel systems if a natural gas boiler is selected.

It’s not so much a matter of if air-to-water heat pumps will become the norm for hydronic systems, but rather when the market will recognize these as viable alternatives and understand how the technology fits into a low carbon building. So instead of asking “What is the cut-out temperature?” the real question is “What is the best way to make use of the heat pump while it can operate?”

Chris DesRoches, P. Eng., Applied Product Manager, Mitsubishi Electric Sales Canada, Inc.

Chris DesRoches, P. Eng., Applied Product Manager, Mitsubishi Electric Sales Canada, Inc.