Dynamic VAV Optimization

May 3, 2022 | By Mark Byvelds and Natalia Malafeeva

An AI approach also allows for a more efficient and cost-effective BMS setup.

We have arrived at the next stage of building control. Moving from pneumatic to DDC (direct digital control) represented a major shift in control equipment and, more importantly, in the feedback coming from building systems.

The next stage—the application of machine learning and artificial intelligence (AI)—builds upon DDC to use that feedback for better control.

What does better control mean? First, it meets the needs of the building and its occupants. Rather than reacting to a space becoming warmer than desired, the control system can predict it will become warmer than required, and make the necessary adjustments.

Second, it is more efficient. Setpoints change constantly based on current or upcoming demand, meaning building systems deliver what is needed at the moment it is needed—and nothing more.

What’s wrong with today’s BMS?

The first question for many may be, “Why?” What is it that AI and machine learning can do that a modern building management system (BMS) cannot?

The answer is adaptability. Machine learning crunches massive amounts of data—better than any person possibly could—to help us understand the complex dynamics of a specific building.

This understanding allows spaces to be conditioned based on what is actually needed as opposed to what we think is needed, especially as the use and occupancy of a building changes.

An AI approach also allows for a more efficient and cost-effective BMS setup. Rather than programming complex, multi-variable strategies for every building, a common cloud-based AI model can be applied to an unlimited number of buildings.

Fault tolerance can also play a significant role. Even a great piece of energy-efficient programming can repeatedly stumble. For example, a temperature sensor receiving direct sunlight in the afternoon which causes the trim and respond static pressure reset to fail time and again as one zone thinks it needs more cooling than required.

The result is missed energy and cost-saving opportunities. Machine learning will identify this pattern of failure; it will flag the issue for investigation and learn to ignore this sensor from the overall strategy, thereby allowing energy savings to be achieved.

When answering the ‘Why?,’ one should also consider the ‘Why not?’ use AI and machine learning.

Depending on the facility, bi-directional Internet access to a cloud platform may not be an option. In this case, an on-premises solution would be needed, which may be cost-prohibitive.

The traditional cost/benefit analysis stands true, as well: what is AI offering that existing controls cannot achieve?

In a practical sense, the Why not? may also be related to fear—fear of losing control over a building or, as a building operator, fear of losing a job.

While understandable, these fears are unfounded. Any AI-based solution needs local oversight to allow the operator to see how systems are being controlled, and to step in and override systems if they become concerning.

The rise of digitalization may bring with it changes in skillsets for building technicians (the ability to support growing connectivity between devices and work with multiple platforms), but the core demands of the role remain.

Mechanical infrastructure still needs to be maintained; it will just become demand-based instead of time-based. Efficiency opportunities still need to be evaluated, and technology will help inform us where to look.

Dynamic VAV Optimization

Thus far, the focus of our company’s Smart Infrastructure—as it relates to AI in building HVAC control—has been on variable air volume (VAV) systems. VAV systems are common throughout the commercial and institutional sector, so there are numerous opportunities for achieving better results through the application of machine learning and AI.

Our Dynamic VAV Optimization (DVO), leverages a building’s existing data sources and control infrastructure to make better decisions.

But what is a better decision? In short, it depends on the priority: users are able to select operation in Green Mode to prioritize comfort and energy efficiency, or Defence Mode to prioritize airborne viral transmission risk reduction.

Green Mode overcomes many of the VAV Optimization challenges conventional BAS strategies struggle with: multivariable decision-making, forward prediction, and fault tolerance, to name a few. Using existing control hardware in the building, the end result has been a roughly 25% energy savings in systems without an existing pressure reset strategy, and a 10% reduction in systems that have one.

Defence Mode allows for a central strategy to be defined and easily updated so sites running DVO are capable of deploying the latest recommendations from ASHRAE and CDC.

Currently, this is a balance of fresh air changes, maintaining target humidity and space temperatures and, in many cases, increasing them compared to conventional set points.

AI really shines when conditions are not ideal, as when a building is struggling to maintain target humidity in the winter; increasing fresh air ventilation is likely to lower indoor humidity, yet higher air change rates are helpful for lowering risk. In a scenario like this, AI logic can determine the lowest-risk point for balancing these ever-changing factors, whereas a person or BMS simply cannot.

CASE STUDY

DVO was recently deployed in the office space of a critical facility in Toronto which remained open and partially occupied throughout the COVID-19 pandemic. In this case, the strategy is to operate in Defence Mode to mitigate transmission risk, then switch to Green Mode as soon as it is deemed safe.

The application of machine learning—in which a database is built to help the engine understand how zones within the building react to ventilation changes and differing environmental conditions—allows for set points to be adjusted dynamically based on what is currently the optimal approach.

When in Defence Mode, this takes into account total air changes, outside air volume, filtration, space temperature and relative humidity, as well as constraints of the ventilation system, such as heating, humidification and airflow capacity.

In Green Mode, the machine learning application adjusts static pressure and supply air temperature based on conditions in each VAV zone to drive down energy consumption as much as possible while still meeting the space requirements. By knowing how the building will react in upcoming weather, it will seek out the lowest energy consumption for fan power, heating, cooling and re-heating, and do so proactively.

With all of these variables at play, and “best case” conditions changing regularly, it is easy to see where machine learning can fit into building control. This approach meets the near-term need of risk management while also supporting the facility’s long-term energy efficiency goals.

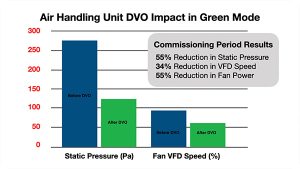

Operational results from DVO operation on one air handling unit.

Although operating in Defence Mode, both Green and Defence modes were tested during commissioning. Results have shown an average reduction in AHU static pressure of 57% while maintaining airflow requirements to terminal units, resulting in an average fan power reduction of 35%, and delivering a pro-rated annual benefit of 126,000 kWh (approximately $19,000 and 3.8 t CO2e) across five AHUs.

As we seek to further reduce energy consumption and move forward on sustainability targets, it is absolutely necessary to use energy wisely. AI and machine learning solutions for HVAC control are here now, growing rapidly, and can be deployed in both existing buildings and new construction.

Mark Byvelds, P.Eng, CMVP, is the national business development manager for Energy Services with Siemens Canada Ltd., and Natalia Malafeeva, M.Eng, CEM, CMVP, is responsible for the operations of the Energy Engineering team with Siemens Canada to support the development and execution of energy projects.