Heating the Historical

December 30, 2020 | By Robert Bean

Designing for human comfort under the constraints of a heritage home in the mountains.

It was no surprise that clients attracted to our engineering firm, Indoor Climate Consulting, were mostly other engineers. In fact, almost 90% of our clients had professional design backgrounds, another 8% were healthcare professionals—primarily physicians—and the additional 2% had various research-based backgrounds. Knowledgeable clients receptive to our firm’s “design for people – good buildings follow” philosophy were the lubricant for designing and building better indoor environmental quality (IEQ) buildings.

It was no surprise that clients attracted to our engineering firm, Indoor Climate Consulting, were mostly other engineers. In fact, almost 90% of our clients had professional design backgrounds, another 8% were healthcare professionals—primarily physicians—and the additional 2% had various research-based backgrounds. Knowledgeable clients receptive to our firm’s “design for people – good buildings follow” philosophy were the lubricant for designing and building better indoor environmental quality (IEQ) buildings.

In the following case study, a family sought us out by searching online for IEQ professionals. Their project was a single-family home designated as a historical building. Located in a campus town nestled in the Rocky Mountains, it was the home the owners were going to be retiring in.

After our initial interview, it was clear they wanted to improve the home’s thermal comfort and air quality through a full renovation of the its interior ergonomics. Still, requirements for maintaining the historical elements prevented them from adding exterior insulation and changing out the windows.

Figure 1. A thermal imaging survey revealed thermal challenges with this historic building.

Another firm was initially hired to reduce infiltration and improve u-values with blown-in cavity insulation. Yet, a subsequent thermal imaging survey revealed areas that still needed remediation work (see Figure 1).

Load calculations based on the final remediated work, verified by another survey and blower door test, led us to recommend a combination of radiant ceilings, floors and walls and panel radiators for thermal comfort. For air quality, we worked with the client to use low VOC finishes and a combination of an ERV and fan/coil fitted with an external MERV 13 filter box.

Heating Design

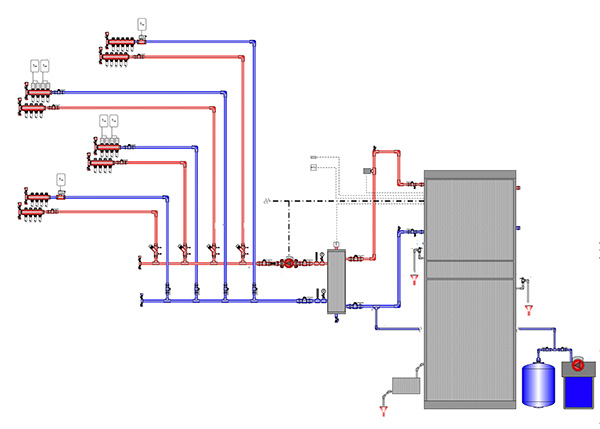

Our practice designed the heat terminals for the heating system around the lowest possible fluid temperatures. This enabled us to extract the maximum efficiency from the boiler when in the space heating mode while avoiding the costs of multiple temperature strategies involving the use of more circulators and controls (see Figure 2).

Figure 2.

To do this, we base loaded using radiant ceilings on the main floor and radiant floors upstairs. The trim for design days was radiant walls and panel radiators.

Engineering these additional radiant surfaces takes a little more tweaking. Still, the payoff in system simplification and improved efficiency is well worth the outcomes.

The one exception was a rogue zone on the main floor. For this area of the house we custom designed a system comprised of a filter box, electric coil and in-line fan. This assembly provided heat for peak loads and constant filtration of recirculated mixed air from the room and ERV.

Ventilation Solution

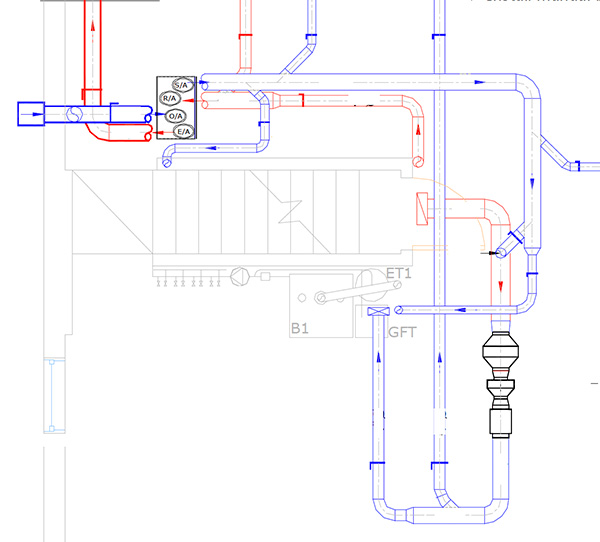

Our three focus areas for ventilation were the house proper, each of the bathrooms and the kitchen. For this, we used an ERV supplied with air filtered through a MERV 11 to 13 inline filter box. The ERV supplied air to each room and extracted air from hallways and rooms from under generous undercut doorways (see Figure 3).

Figure 3.

The upstairs bathroom had a dedicated exhaust air fan. In the kitchen, the clients were receptive to using an induction cooktop rather than a gas range, and with the hood covering more than 120% of the stovetop and sufficiently low enough, we could reduce the exhaust hood flow to 275 cfm.

Discussion

On a relative scale, this was one of our firm’s smaller but more interesting projects, driven first by doing whatever was possible to the enclosure within the historical buildings’ limitations.

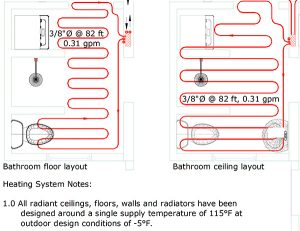

Figure 4.The high heating load in the main floor laundry/bathroom required both radiant ceilings and floors.

Engineering the radiant surface areas to fit a common lowest temperature was a welcome solution. Some zones required both radiant floors and ceiling surfaces, or a combination of radiant floors and walls or panel radiators to achieve thermal comfort (see Figure 4). We also had to develop a site-fabricated fan/coil with electric heat for the rogue main floor zone’s peak load.

The use of induction instead of a gas range and a generous sized deep sump range hood enabled a low exhaust flow for more effective and quiet operation.

The ERV worked to ventilate the home plus serve the fan/coil filtration unit on the main floor. This turned out to be especially useful for improving indoor air quality in the past years of forest fires.

None of this would have happened had the clients not prioritized this historic home’s indoor environmental quality. By seeking out the IEQ professional, they achieved a lifetime of desired outcomes. <>

Robert Bean is director of healthyheating.com and founder of Indoor Climate Consultants Inc. He is a retired engineering technology professional who specialized in the design of indoor environments and high performance building systems.

Robert Bean is director of healthyheating.com and founder of Indoor Climate Consultants Inc. He is a retired engineering technology professional who specialized in the design of indoor environments and high performance building systems.