Products we need

February 18, 2020 | By John Siegenthaler

Suggestions for five technologies and products that could help move the hydronics industry forward.

Product innovation has moved the North American hydronic industry a long way over the last 50 years.

In the 1970s, a typical residential hydronic system used a fossil fuel boiler to supply two or three zones of baseboard with scalding hot water. Today, some systems use geothermal or air source heat pumps, possibly supplied by renewably-generated electricity, to supply room-by-room comfort using bathtub temperature water circulating through radiant panels. Continuous improvement is essential to maintaining a healthy industry, especially if that industry expects to gain market share against competing technologies.

To promote future growth, new products and installation methods should (in no particular order):

• make systems easier and faster to install.

• deliver equal or better comfort than their predecessors.

• demonstrate increased efficiency.

• improve system reliability and reduce maintenance.

• correct deficiencies in existing products or installation methods.

With these objectives in mind, the following are my thoughts on five products I think could further enhance North American hydronics technology;

1. A vapor-tight insulation system for circulator volutes

If you’ve used cast-iron circulators in any type of chilled water cooling system, or in earth loops for geothermal heat pumps, you’ve likely seen what happens to the volute, steel flange bolts and even steel handles on isolation flange valves when they rack up a few operating hours well below the dewpoint temperature of the surrounding air. All these components quickly develop surface oxidation. (figure 1 shows an example.) Over time the orange condensate drips onto anything below it. This “superficial” rust doesn’t compromise the circulators performance, but it does make a mess. The obvious solution is to add a vapour-tight insulation envelope around all parts of the circulator other than the motor can and wiring compartment. Some manufactures offer molded foam clam shells that fit specific circulators— usually commercial-sized ECM products. These can limit condensation if they are properly sealed at all locations where air could contact any chilled metal surface.

Wouldn’t it be nice to have an insulation/vapour barrier system that could fit any circulator that may have to operate at sub-dewpoint temperatures? Perhaps a block of solid insulation material that could be easily molded, on site, to the shape of the installed circulator, and then attached as two mating parts. Maybe a hollow plastic shell that could be fit around the installed circulator volute and flange joints and then filled with expanding foam. An elastomeric gasket would be part of either approach to provide the air-tight seal with the circulator’s motor can. The portion of the circulator that contacts the insulation could be sprayed with a “release agent” that prevents strong bonding in case the insulation had to be removed to service or replace the circulator.

2. A simple, inexpensive temperature controller for variable speed ECM circulators

Over the last 25+ years I’ve designed many hydronic systems that had one or more circulators with standard PSC motors operated by variable speed controllers. The controllers used a combination of AC wave chopping and frequency control to vary the speed of the circulator.

However, the circulator world is changing. Those familiar wet-rotor circulators with PSC motors are about to go the way of 100 watt incandescent light bulbs. I suspect they will be out of production within the next five years. Circulators with higher efficiency ECM motors are quickly becoming the new normal.

Variable speed controllers using wave chopping and frequency control cannot be used with ECM circulators, so it’s just a matter of time until those controllers follow PSC circulators into the annals of hydronic history. The good news is that many of the new ECM circulators can be speed-controlled using a 0-10 VDC input signal (not to be confused with the standard 120 VAC electrical power supply). A typical scenario is for the circulator to remain off until the control signal reaches 2 volts. The circulator’s speed increases in direct proportion to the control voltage, reaching full speed at 10 volts. What’s needed are simple and inexpensive controllers that generate a 0-10 VDC output signal in relationship to some temperature-based condition. The latter could be a user-set “target” temperature, with circulator speed selectable as increasing or decreasing as the temperature measured by the controller varies from the target value. This function allows for supply water temperature control as well as boiler anti-condensation protection.

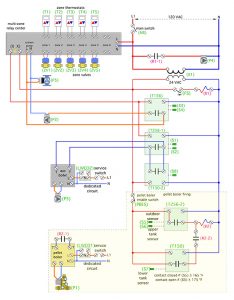

The controller should also handle differential temperature control, such as used in solar thermal systems or biomass boiler systems. It should also be able to provide variable speed injection mixing based on either a fixed target supply temperature or a target temperature calculated using outdoor reset logic. All these functions are just selectable code within the controller’s firmware. The controller should have connections for up to three temperature sensors, as shown in figure 2.

3. A multi-function controller for biomass boiler systems

There are lots of applications for boilers burning wood pellets or chips. These “biomass” boiler systems require several control functions including boiler anti-condensation protection, boiler firing based on two or more temperatures within a thermal storage tank, variable speed injection of heat into a distribution system, differential temperature control to prevent auxiliary heat from entering storage, coordinated operation of an auxiliary boiler and zoning.

All of these functions can currently be provided by combining several independent single-function controllers along with an assortment of relays. Although these “multi-box” control systems work, their installation and programming can be challenging. I can attest that this has been a significant barrier to successful biomass boiler installations, especially in residential or light commercial applications.

This situation could be greatly improved if the market provided an integrated controller to handle all necessary control functions for these systems (see figure 3). The functionality exists, it’s just a matter of repackaging it in one box.

4. Indirect tanks with larger coil heat exchangers

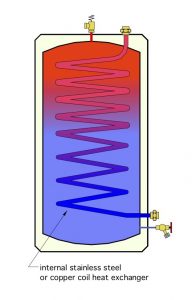

The future of hydronics is low water temperature. Contemporary heat sources such as geothermal water-to-water heat pumps or air-to-water heat pumps typically max out at water temperatures in the range of 120-130F. That’s hot enough for many types of heat emitters, such as well designed radiant panels or panel radiators. It’s also sufficient to create domestic hot water at perhaps 110 to 115F—if there’s a suitable heat exchanger between the source water from the heat pump and the domestic water.

Most of the currently available indirect water heaters in North America are very limited in such applications. The internal coil heat exchangers in these tanks don’t have sufficient surface area to transfer heat from a much lower temperature heat source to the domestic water at the heat output rate of the source and at a minimum temperature differential of only 5 to 10F. The result will be short-cycling, heat pumps locking out on fault conditions and complaints about inadequate domestic hot water. Most North American indirect water heaters were developed assuming a boiler would be the heat source, supplying water to the coil heat exchangers at temperatures of 180-200F. Swap in a heat pump and you have a very significant heat transfer “bottleneck.”

One solution is to use an external stainless steel heat exchanger sized for very low approach temperature differences. This works, but it’s arguably more complex than an indirect water heater.

Another solution would be to increase the surface area of the coil heat exchanger inside indirect tanks. Coils with three to five times the surface area of a typical indirect are needed. Such coils would likely span from the bottom to the top of the tank as depicted in figure 4.

The coils could be made of either stainless steel or copper. The water passing through them could be from the heat source, or it could be domestic water. The later “reverse-indirect” concept allows the tank to provide domestic water as well as buffering for zoned space heating loads. It also allows the pressure vessel to be made of carbon steel, which is more affordable than stainless.

I would also suggest that such tanks have R-24 F•hr•ft2 /Btu insulation on all surfaces and ample ports for a variety of applications. Think of such tanks as high quality “Thermos bottles,” capable of storing heat for several hours, or perhaps a couple of days with minimal temperature drop.

5. Peel & stick elastomeric foam pipe insulation that sticks

My last plea is born out of frustration. I’ve had many occasions to see (and fix) peel & stick elastomeric foam pipe insulation with seams that have reopened only a few weeks after installation. I suspect that I’m not the only one who has experienced this problem.

I’ve fixed it using 1.5-in.-wide high quality vinyl electrical tape centred along the slit line. This works, but it shouldn’t be necessary. Perhaps the product branding should change from “peel & stick” to “peel, stick and stay.” Perhaps some of these ideas will come to fruition to advance the North American hydronic market.