The case for stainless steel water heater tanks

March 21, 2017 | By Robert Waters

Despite the higher price tag, stainless steel water heater tanks are often more cost effective when lifecycle costs are compared and should be presented as such.

Domestic water heating appliances are the real foot soldiers of the mechanical world. They are constantly exposed to a very hostile environment and their hard work is mostly ignored. On the water side of the heater, minerals, oxygen, chemicals and sediment can all attack. On the combustion side, high temperatures, thermal stress and flue gas condensate can all create havoc with the materials.

When it comes to maintenance, domestic hot water (DHW) heaters are virtually ignored. Most homeowners take their water heaters for granted and only notice them when they are not working or are leaking. Check the anode rod? Flush out the sediment? Have a maintenance program? Forget it, we are not bothering with that. It is no wonder that most DHW appliances have fairly short life spans.

Related: Mechanical room retrofit

Could this short lifespan be improved? Using DHW heaters made of stainless steel is one way to improve life expectancy. Stainless steel is a strong, durable material that can better stand up to water side and fire side attacks, giving the heater a fighting chance to provide a long service life. Stainless steel’s only real drawback is its high material and fabrication cost. In the ultra-competitive DHW heater market, this high cost is a big challenge to overcome.

WHAT IS STAINLESS STEEL

Stainless steel is a generic name for iron alloys with a minimum of 10.5 per cent chromium. Other elements such as nickel, molybdenum, titanium, and carbon can also be added to provide corrosion resistance, strength and formability. There are many different combinations of these different metal alloys that produce a particular “type” and “grade” of stainless steel. Just saying something is made of stainless steel does not tell the whole story.

If someone said “Get me some plastic pipe” what would you bring? PEX, CPVC, polyethylene? All of these are “plastic” pipes, yet all have very different properties, strengths and applications. It is the same with stainless steels. There are over 150 grades of stainless steel, all having very different properties and applications. Stainless steel used in domestic hot water heaters are most commonly made from only a few grades of stainless steel, typically types 304, 316L, 316Ti and 444.

The difference between these grades is in what concentration of alloys is in them. All “300” grades of stainless steels contain approximately 18 per cent chromium and 10 per cent nickel. Both of the 316 grades also contain two per cent molybdenum, and 316Ti grade adds one per cent titanium to the mix. The molybdenum gives 316 grades better overall corrosion resistant properties than 304 grade, particularly higher resistance to pitting and crevice corrosion in chloride environments. Titanium in the 316Ti grade gives it excellent formability and strength. 444 grade does have chromium and molybdenum, but it does not have any nickel. Generally speaking the more nickel, molybdenum and titanium there is in the mix, the better the corrosion resistance and strength, but also the higher the cost. Take a closer look at the grade when someone says they have a “stainless steel” water heater because they are not all the same quality

USING STAINLESS STEEL IN DHW HEATERS

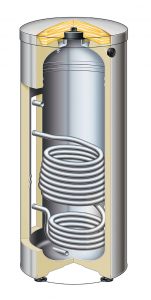

Stainless steel is used in all different types of water heaters. It is most often seen in use in indirect DHW heaters and in condensing tankless water heaters. Indirect water heaters incorporate an internal heat transfer coil connected to a boiler or a solar collector loop. They are more common in Europe than in Canada due to the predominance of hydronic and solar water heating systems in Europe.

Stainless steel construction makes up a big part of these European indirect markets. In Canada, both stainless steel and glass lined steel indirect tanks are available, with stainless steel tanks usually carrying the higher price tag. In non-condensing tankless water heaters the heat exchangers are typically constructed of copper. With the push to higher efficiency condensing units, heat exchangers are either all stainless steel, or a combination of a primary copper and a secondary stainless steel heat exchanger. The direct-fired tank type water heater is still king in Canada’s water heater market. Carbon steel with glass linings dominates this sector.

Stainless steel is often used in tankless or direct-fired tank condensing water heaters.

When squeezing more efficiency out of these appliances, the flue gases must be cooled below the dew point to release the latent heat of the fuel. The resulting condensate is basically distilled water vapour from the gas combustion products and it has a very low pH and high acidity. This acidic condensate water must be disposed of by piping it to a drain, but the bigger concern is its corrosive impact on the water heater heat exchanger surfaces.

Heat exchangers made of regular steel or copper have a harder time standing up to this flue gas condensate for long. Stainless steel is a great material choice due to its high corrosion resistance and flexibility, which gives it the ability to be formed into intricate heat exchanger shapes. There are currently numerous brands of condensing tankless water heaters employing stainless steel heat exchangers. This enables them to encourage complete flue gas condensing in the heat exchanger, and results in high EF ratings of up to 0.97.

Tank type water heaters with condensing technology are also now starting to be used more often, especially with changes to some building codes requiring higher water heater efficiencies. There are two common types of construction seen in this market. Glass lined tanks are being constructed with fully submerged secondary condensing heat exchangers. Both the outside (water side) and inside (fire side) of the heat exchanger coil is glass lined, with the glass lining on the inside providing protection against flue gas condensation. Tank models with all stainless steel tank and coil construction are not as common, but there are several available with this type of all-stainless construction.

The glass lined tanks do carry a lower initial cost and only time will tell how well the heat exchangers stand up to the aggressive condensing environment. These new condensing tank type water heaters are able to achieve higher efficiencies than conventional direct-fired water heaters, with thermal efficiencies between 90 and 96 per cent. As governments push water heater efficiency regulations higher and higher, we are sure to see more innovative high efficiency tank type water heaters come to the market.

ADVANTAGES OF STAINLESS STEEL CONSTRUCTION

Looking more closely at tank type water heaters, you can find both glass lined and stainless steel construction for most types of direct-fired, indirect internal coil and straight storage tanks.

So, what are the advantages of stainless steel over glass lined? How can you convince customers to invest more in a stainless steel tank? The biggest advantage of stainless steel is its natural resistance to corrosion from fresh water resulting in a much longer service life. Due to their composition of corrosion resistant metal alloys, stainless steel tanks are stronger and more durable compared to glass lined ones. Stainless steel water tanks have a protective oxide barrier on the water side that prevents corrosion naturally.

On the other hand, glass lined tanks rely on the glass lining to provide a barrier between the carbon steel and the water. Given the chance, oxygen and chemicals in the water will attack the steel and rapidly corrode it. As it is very nearly impossible to apply any protective coating perfectly (without microscopic cracks or pinhole defects in the protective layer) glass lined tanks include a sacrificial anode rod installed inside the tank.

Related: How to solve installation errors

The sacrificial anode rod will become depleted over time and when this process has completed, electrolysis will begin to eat away at the exposed areas of steel on the tank interior. How fast the anode depletes will depend on the water quality, and the water usage rate. The sacrificial anode typically lasts from three to five years and it is possible to replace the anode to prevent further destruction.

In reality, the periodic check and replacement of the anode is often neglected and the tank develops a leak, resulting in the entire appliance being replaced. Unlike glass lined water tanks, stainless steel tanks do not need a “sacrificial anode” in order to prevent corrosion on its surface. This means there is no need for inspection or replacement of anodes, saving time and cost in maintenance over the life of the water heater.

Due to this higher durability and resistance to corrosion, you will often find that stainless steel tanks have a longer warranty, with some manufacturers offering lifetime warranties on tanks.

Stainless steel water tanks also have the advantage of being lighter weight compared to glass lined tanks making them easier to transport, handle and install. The wall thickness of stainless steel used in tanks is typically much thinner than a comparable steel tank with glass lining. Add on top of this the weight of the glass lining itself, and the weight of a glass lined tank is often significantly more.

Stainless steel tanks require less attention when being transported, unlike glass lined tanks, which have the delicate glass lining that can be damaged when in transit. If the glass lining of a tank is damaged or cracked due to rough handling during transportation or installation, it may not be known until the tank suffers premature failure.

Stainless steel tanks are typically able to withstand higher temperature water than glass lined tanks, with temperatures in excess of 180F not presenting any issues. Some glass lined tanks are prone to stress when subjected to elevated temperatures, leading to a higher risk of damage to the glass lining. Temperatures above 160F can become an issue for some glass linings. Applications such as solar water heating and some commercial-industrial applications can see high temperature water storage requirements.

It is advisable to check with glass lined tank manufacturers to find out what the recommended maximum operating temperature is. Stainless steel tanks are often a better choice for high temperature applications.

There is no doubt that the initial cost of stainless steel tanks is higher than glass lined water tanks. But the lifecycle cost of glass lined water tanks may become higher for the reasons noted here. When those lifecycle costs are compared, stainless steel tanks are often more cost effective in the long run and should be presented as such to customers.

Robert Waters is president of Solar Water Services Inc., which provides training, education and support services to the hydronic industry. He is a mechanical engineering technologist graduate of Humber College and has over 30 years experience in hydronic and solar water heating. He can be reached at solwatservices@gmail.com.