Turn Down the Volume

May 30, 2023 | By Dave Demma

Combatting excessive noise levels in HVAC and refrigeration systems: likely sources and fixes.

(Alacatr/Getty Images)

We live in a noisy world. Airplanes, automobiles, construction sites, loudspeakers in public areas, television, radio or streaming music, and also that obnoxious individual in the airport who believes you’re interested in listening to their conversation, or their favourite Instagram real of the moment.

The incessant snorer in the room sharing a common wall to your hotel room, and even the annoying dullness of white noise. For example, the restroom exhaust fan that has been on for several hours. However, there are some studies that suggest some amount of light background noise will increase worker productivity. Personally, I find this type of noise very distracting.

And as odd as it may seem, being out in the serenity of nature away from the drumbeat of the city, the absence of noise almost becomes deafening.

Then there’s the constant droning of that package HVAC unit or chiller providing the ultimate comfort in your building, or the refrigeration equipment tasked with keeping your Häagen-Dazs vanilla swiss almond at the perfect temperature.

The unit of measure for sound is the decibel. A whisper is about 30 dB, normal conversation is about 60 dB, and a motorcycle engine running is about 95 dB.

Noise above 70 dB over a prolonged period may start to damage your hearing. Loud noise above 120 dB can cause immediate harm to your ears.

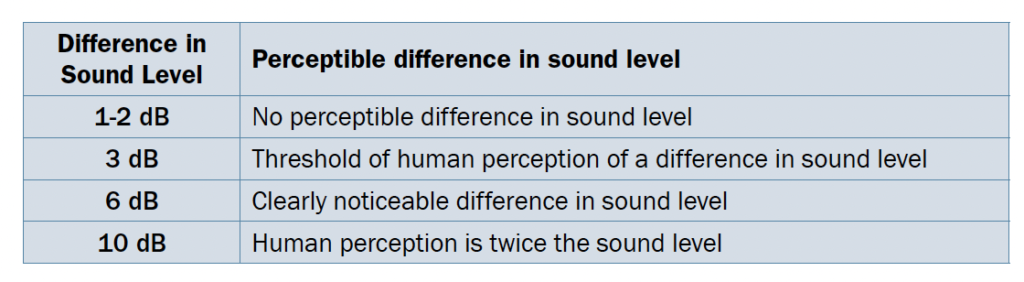

The chart below (Figure 1) provides some perspective as to the human ear’s ability to perceive sound.

Figure 1. Sound perception by the human ear.

Noise levels in the workplace can be annoying, result in a loss of worker productivity, and even hazardous.

A workplace has hazardous noise if one needs to raise their voice to be heard. Hazardous noise can be best described as (1) too high pitched, (2) too loud, or (3) too long, or a combination therein. And repeated exposure to hazardous noise can lead to permanent hearing loss.

Let’s look at some specific steps that can be taken in order to reduce the noise generated by HVAC and refrigeration equipment.

Compressors

Compressors are noisy. The reciprocating action of the internal parts will cause vibrations that can be transmitted through a building’s structure. Vibration isolation mounts can reduce these vibrations (note the vibration mounts in the opening photo above).

In addition, larger systems with long refrigerant piping runs and remote condensers are unpredictable. Variations in the piping configuration, the pattern of the refrigerant gas flow, line sizing and operating pressures have a great impact on noise generation.

A particular combination of gas flow and piping can result in a resonant frequency which may amplify the sound and vibration to an undesirable level.

Refrigerant gas pulsation from the compressor can also be similarly amplified. A discharge muffler, which employs a series of baffles and/or pressure drop to obtain an even gas flow will dampen the discharge gas pulsations to a frequency that is not so objectionable.

There might be occasions when a combination of operating conditions, mounting and piping arrangement may result in a resonant condition. This will tend to magnify compressor pulsation and cause a sharp vibration, but not necessarily be a noise problem.

If approved by the particular compressor manufacturer, muffler plates have been found to dampen excessive pulsation. The muffler plate fits between the discharge valve and the compressor body and has a number of muffling holes to provide the proper characteristics for the particular compressor displacement. The muffling holes break up the pattern of gas flow and create sufficient restriction to reduce the gas pulsation to a minimum.

As a final measure, a compressor noise blanket can be applied (as pictured), an approximate 5 dBA reduction can be achieved.

Fan Motors

Condenser fan motors are available in varying RPM ratings. The higher the RPM, the greater the air flow through the condenser, so this is great for maximizing capacity. However, the higher the RPM the noisier the condenser will be too.

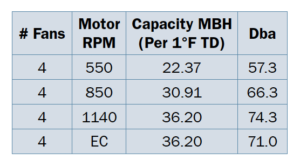

The chart below (Figure 2) shows comparative capacity and dBA rating for a four-fan condenser (1X4). There is a definite tradeoff between noise and capacity.

Figure 2. Comparative capacity and dBA rating for a four-fan compressor.

For a given Btu capacity, the slower the motor speed, the larger the condenser will need to be, which will add cost.

However, certain municipalities might have specific noise requirements which would require the use of a more expensive slower RPM motor.

Also, the chart illustrates that the EC motors provide the same capacity as the higher 1140 RPM motor, but they have a lower dBA rating.

Reducing the motor speed certainly will reduce the noise emitted by the motor/fan combination. This can be achieved with variable speed EC motors or applying a variable frequency drive (VFD) to standard VFD rated motors.

(Adobe Stock)

Protection = Prevention

As I’m getting into my senior years, I often reflect on how the human body loses some of its marvelous capacity over time, and then I dovetail that with some of the stupid things I did in my early years when I believed I was invincible.

For example: In college, I attended a Hot Tuna concert. This was a blues band, with the primary members being Jack Cassidy (bass guitar) and Jorma Kaukonen (guitar) from the Jefferson Airplane.

I imagine that the sound level was well over the 100 dB level, as my ears were still sore the next day.

Then there were the numerous times working in extremely loud machine rooms without any ear protection.

All jurisdictions in Canada have the requirement for workers to use personal protective equipment (PPE). And employers are responsible for making sure that PPE requirements are being followed. In the U.S., OSHA (Occupational Safety and Health Administration) requires the following:

Employers shall make hearing protectors available to all employees exposed to an 8-hour time-weighted average of 85 decibels or greater at no cost to the employees. Hearing protectors shall be replaced as necessary.

Whether one’s employer provides it or not, I would strongly recommend that every technician acquire some ear protection for those long days replacing a compressor or otherwise occupied in a noisy machine room.

It’s always easier to prevent damage to the body, then attempt to repair it after the fact. <>

Dave Demma holds a degree in refrigeration engineering and worked as a journeyman refrigeration technician before moving into the manufacturing sector where he regularly trains contractor and engineering groups. He can be reached at ddemma@uri.com.

Dave Demma holds a degree in refrigeration engineering and worked as a journeyman refrigeration technician before moving into the manufacturing sector where he regularly trains contractor and engineering groups. He can be reached at ddemma@uri.com.