Kohler WasteLab looks to repurpose industrial waste into new products

June 15, 2018 | By Jillian Morgan

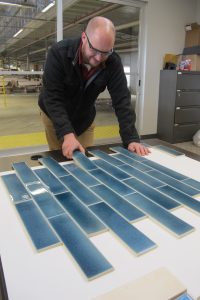

WasteLab re-purposed ceramic tiles.

Kohler WasteLab associates shared their latest work to repurpose industrial waste materials during a Facebook Live panel.

The team’s first project uses pottery cull, iron slag, leftover glazes and enamel powder to create ceramic tiles, which Kohler expects to begin marketing under the Ann Sacks brand in 2019.

“As a manufacturer we have a responsibility to the world to behave differently,” Theresa Millard, WasteLab project manager, said. “Industrial waste streams are an enormous problem around the world.”

The idea for the project originated in 2013 at the company’s annual Innovation for Good retreat. The lab team members said they hope to create additional scalable product offerings from these nonhazardous waste materials, which otherwise would be sent to the company’s landfill.

Joshua Boyce, senior project engineer at WasteLab, said the challenge, however, is that Kohler is not a raw materials company.

“We’re having to do that ourselves literally out of a dumpster,” he said during the panel.

Boyce says slag, which came from Kohler’s cast iron division, caught his eye due to its similar appearance to lava rock. The team ground up the waste by hand and created a glaze. After this process of experimentation, the goal is to replicate it on a larger-scale.

“Of course we want to make a profit, we want to make a nice product to sell but we want to reduce the waste that’s going into the landfills,” Monty Stauffer, industrial designer at the lab, said. He said ceramics materials, resin materials and iron dust can also be used as something “beautiful” or “useful.” www.kohler.ca