New heat pump technology remedies past issues

February 15, 2019 | By Ian McTeer

Certainly all of us have been truly disappointed by something or other at least once in our lives. Perhaps your new service vehicle spends more time in the shop than on the road or you are working for a seemingly great new service company only to find out the “every other weekend off” policy is just so many words.

Disappointments, say psychologists, life coaches and inspirational thinkers “are not meant to destroy you; they are meant to strengthen you.” So it was with me and air source heat pumps (ASHP).

I was over-the-top about ASHPs: “Hey, three watts of heat out for every one watt of electricity in!”

What happened to dissolve my original enthusiasm; why did I begin to feel so fundamentally disappointed by heat pumps?

Starting in the mid 1980s, a partner and I formed a contracting business and our little company seemingly existed to sell only ASHP.

We aligned ourselves with a premium brand, took numerous technical and sales-related courses and never missed an opportunity to sell a heat pump.

Such opportunities, as it turned out, were few and far between.

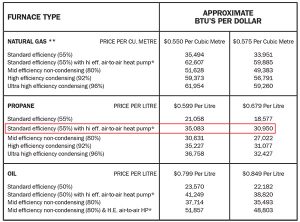

Sales information floating around at the time made some, what I categorize as, “far reaching” claims. Figure 1 seems to indicate adding-on a heat pump to a 55 % AFUE furnace burning liquid propane (LP) might be a wise choice. Yikes!

The asterisk annotating the standard efficiency furnace with add-on ASHP cautioned “air to air heat pump efficiency varies with outdoor temperature. Estimates are approximate for Southern Ontario.”

There are rules to be followed and techniques to be learned and utilized properly in the field.

Bin weather data compiled by Lennox for U.S. cities and some selected Canadian cities provided more convincing data that an ASHP could work in our cold climate.

The Lennox table provided an average number of hours each city might experience in a certain temperature range. For example, bin data indicated average Toronto temperatures could be in the 25F (-3.8C) to 60F (15.5C) range for 4,691 hours–a good chunk of the winter.

This is prime ASHP weather, as any properly designed and installed ASHP can easily have a balance point at or even below 25F (-3.8C).

These are not load hours, but simply hours of heating opportunity for an ASHP unit.

Montreal’s bin data allowed for 4,307 hours between those temperatures. Indeed, ASHPs installed in Quebec with matching electric indoor sections or added on to oil furnaces were encouraged by government financial incentives for many years.

DISAPPOINTMENTS HAPPEN

A federal government incentive program aimed at encouraging homeowners to move away from oil-fired heating systems seemed like the perfect opportunity to get more ASHPs into the field. However, in major cities, natural gas became the fuel of choice.

When an opportunity to sell a heat pump did present itself, too many clients balked at the price. Some said things such as, “The quotes I got from other contractors are cheaper, and none of them recommended any duct renovation,” as if we were trying to sell unnecessary work.

Selling heat pumps was not working for us, and when I look back on it, perhaps this disappointment was a blessing in disguise.

Then, our premium brand ASHP manufacturer decided to leave the HVAC business, literally overnight.

The manufacturer had been in the midst of developing a “northern” air source heat pump that included some revolutionary new technology; however, the unit had a nasty habit of pumping down during defrost.

A manual reset low pressure switch terminated compressor operation leading to one or more service calls.

Rather annoyingly, if the unit had been operating above balance point at the time of compressor lock-out, auxiliary heat did not take over automatically.

Frustrated homeowners would have to switch to “emergency heat” allowing furnace-only operation for the duration. Ultimately, with no solution to the pump down problem, and no factory support, these disappointments dampened my spirit.

I never again installed another ASHP in a consumer’s home.

Notwithstanding my lack of sales success with ASHPs, some units installed by other mechanical contractors did work well when all the rules (including maintenance) were followed.

I serviced ASHP equipment with 25 years or more of service that unequivocally saved many Btus for satisfied homeowners.

Why didn’t the majority of contemporaneously installed ASHPs provide such value and comfort? Problematic installations typically have the same cast of usual characters: manufacturers, contractors (I made some mistakes too) and homeowners are all worthy of some blame.

MANUFACTURERS, WHAT WERE YOU THINKING?

There is no doubt that conventional ASHP equipment works perfectly well in less severe winter climates.

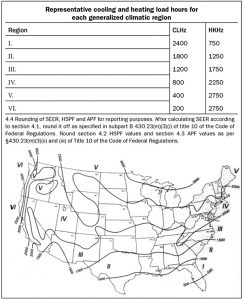

AHRI Climate Region lV (see Figure 2) is the standard for rating Heating Season Performance Factors (HSPF) for all heat pumps sold in North America.

Although Region V (most of Canada) provides many opportune heating hours for an ASHP, complicating factors such as heavy snowfall, frequent defrost periods and low temperature rise were never adequately addressed until very recently.

- Low temperature rise: Even when equipment worked perfectly well, heated air out the registers felt cold, not cool, but cold. ASHP units typically produced heated air in a temperature rise range of 20F to 30F; air out the registers rarely ever exceeded 105F (41C) in my experience. Then, during defrost, had the auxiliary heat-during-defrost feature not been utilized, even colder air chilled the homeowner. Though the conditioned air produced by standalone ASHPs was warm enough to heat the house, it simply was not comfortable for the consumer. Uncomfortable people fiddle with thermostats. Modern thermostats have a built-in time delay deliberately meant to frustrate the fiddlers and twiddlers. Uncomfortable homeowners revert to running extra space heating devices eliminating any system efficiency gains and, of course, they complain loudly.

- Defrost Controls: Some early ASHP units I encountered in the field had nothing more than a pressure switch connected to a copper sensing tube mounted inside the outdoor coil just below the top row of tubes. The sensing tube would fill-up with grass clippings, dirt, bugs and ice thus preventing the pressure switch from tripping the reversing valve. Outdoor units would freeze solid just like the proverbial ice cube. Later, controls based on a combined time and/or temperature differential were used. Almost universally, this type of defrost control ended-up reverting to a timed defrost–often every 30 minutes whether defrost was needed or not. Defrost switched the system into cooling mode and triggered a call for auxiliary heat meant to temper the air delivered to the space. Command-based defrost controls were useless in a northern climate–it was not until a manufacturer developed demand-based defrost controls in the mid-80s that the situation improved. Did I ever mention that defrost is NOT a problem for ground-source heat pumps?

- Contractor technical and sales training: Several major players such as Carrier, Lennox, General Electric (later Trane) and Westinghouse Electric offered comprehensive training for dealers interested in heat pumps. However, considering all the players in the early ASHP market, there was not enough training of value. There was far too much “irrational exuberance” or sales propaganda floating around; even technical courses were run by sales people. The fact is this: ASHPs sales and installation in our cold climate requires a well-engineered approach using properly trained installers and technicians.

CONTRACTORS: TOO MANY MISTAKES

I said I had encountered some early-day ASHP installations that worked well providing a level of satisfaction for the end-user. But as a technician and service rep I attempted to correct far too many installed systems that simply existed outside of any governable rules:

- Many contractors improperly sized heat pumps. Without a load calculation it is impossible to know if the existing air handling system can accommodate any given unit selection and an accurate balance point cannot be established.

- Inadequate indoor airflow and poor air distribution. Heat pumps typically require more airflow than a straight cooling unit (450 cfm/ton); an ASHP coupled to an air handler with electric heat requires more air than straight cooling. These rules too often precluded retrofits; only an engineered new installation or complete renovation job provided satisfactory results for early ASHPs.

- Mismatched indoor coils sized to fit into tiny plenums installed on furnaces not capable of high static operation too often resulted in damaged compressors, which were very difficult to repair in winter. ASHPs are best installed in warmer months. Evacuation, dehydration and charging procedures can then be completed with greater precision than in cold weather. Any manufacturer supplied charts for charge checking in the winter are temperature range specific; require proper indoor airflow and a completely defrosted outdoor coil.

Less than ideal site selection created defrost and poor performance problems:

- ASHPs should not be sited where exposed to prevailing winter winds. It was not unusual to find outdoor units partially covered or even buried in snow drifts.

- Any ASHP must have adequate clearance around and above the outdoor coil to prevent recirculation of its own air.

- All units must reside well above anticipated snow levels providing drainage thus preventing coil melt-water from backing-up inside the unit potentially damaging the outdoor coil.

- Outdoor units cannot be installed where water dripping from overhead might coat the outdoor coil with ice.

- Dripping water can freeze onto the vertical discharge fan blade throwing it out of balance sometimes breaking off a shard of metal capable of puncturing the outdoor coil.

- Improperly set balance points forced many ASHPs to run in standalone heating mode too long after the house load exceeded the outdoor unit’s capacity. Or, perhaps even worse, the balance point was set too high thus handing off the load to the more expensive auxiliary heat source sooner than necessary.

I have darkened the doors of heat pump disappointment city, a bleak place for a normally cheery fellow. Its streets were littered with ASHP marketing propaganda, unread instruction manuals, incomplete commissioning reports and unhappy customer letters. Yet my devotion to heat pumps has not been dashed.

I am strengthened by the recent introduction of fantastic new technology:

- Better scroll and rotary compressor technology utilizing inverter drive vapour injection has created an entirely new class of heat pump: the cold climate air source heat pump (ccASHP).

- ccASHP can be easily zoned even mixed and matched with fan coils, indoor heads, ceiling cassettes or air handlers and some can heat in one part of the building and cool in another all at the same time.

- ccASHPs have better defrost control, only defrosting when absolutely necessary.

- More reliable electronic controls and sensors provide installation and operational data making servicing and repairs much simpler.

- Side discharge outdoor units can be wall mounted and are much quieter than conventional ASHPs.

- Ground source heat pumps (GSHP) have none of the outdoor unit problems: no defrost issues, no problem with north winds, no fan blade worries.

- Non-subsidized GSHPs are unfortunately still a first-cost issue for too many homeowners. Commercial and institutional applications are much more common especially condominium projects utilizing one large shared ground loop providing heating and cooling for dozens, even hundreds, of individual indoor units.

Perhaps I am, once again, over the top with enthusiasm for heat pumps, I am certainly spreading my good news in what one might take be an exercise in propagandistic cheerleading.

However, I am convinced that ASHPs are now the most cost effective way to provide not only reliable operation but comfortable HVAC to the greatest number of residential households. Yes, there are still rules to be followed, techniques to be learned and utilized properly in the field; maintenance-free is still a hollow slogan. <>

For installation pointers see HPAC February digital edition.

Ian McTeer is an HVAC consultant with 35 years experience in the industry. He was most recently a field rep for Trane Canada DSO. McTeer is a refrigeration mechanic and Class 1 Gas technician.