Heat Pumps: What is Inverter Technology? [30 Mechanical Minutes]

June 9, 2023 | By HPAC Magazine

Ian McTeer and Gerry Wagner sit down with HPAC to discuss the facts behind inverter technology and how it is making heat pumps better.

Interest in heat pumps is growing rapidly as homeowners are learning more about the technology through government incentive programs and exposure through mainstream media. Being on the front lines, HVAC contractors are doing their part to educate consumers about what heat pumps are and why they make sense for efficient space heating and cooling.

The latest installment of HPAC magazine’s 30 Mechanical Minutes, our free educational webinar series, turned its focus on getting into the specifics of the latest generation of cold climate heat pump technologies.

Joining HPAC editor Doug Picklyk in this episode were two regular magazine contributors, Ian McTeer and Gerry Wagner. This edition of 30 Mechanical Minutes was sponsored by Olimpia Splendid.

To begin, McTeer explained how the industry has been trying for years to improve comfort while reducing electrical consumption on air conditioners and heat pumps using mechanical processes, such as two-step compressors, where the unit is only partially loaded to conserve energy when possible. “The mechanical method worked reasonably well, but an inverter does a much better job,” says McTeer.

How does an inverter work?

As McTeer explained: an inverter drive takes incoming A/C voltage and converts it to DC using a rectifier. The resulting DC voltage powers the inverter circuit that produces an A/C voltage at variable frequency, so the compressor motor speed is controlled by the A/C Hertz delivered to it. A combination of sensors and smart thermostats control the logic and decide what speed the compressor should run at based on the load condition at the time.

“I’d have to say that the inverter drive compressor is probably one of the most significant advances in the HVAC industry, especially residential products,” says McTeer.

And Wagner has stated many times that the inverter compressor is “The greatest invention in the HVAC industry in my lifetime.”

He points to heat pump products now having seasonal energy efficiency ratings (SEER) in the high thirties. “I never thought I’d say that in my lifetime. And that’s all a result of the inverter compressor bringing low ambient heating down to -5F (-20C),” says Wagner.

He also credits the inverter compressor for allowing multi-zone mini-split systems, something that wasn’t possible prior to the inverter compressor. And he welcomes the introduction of soft start technology—inverter compressors don’t start at 3,600 rpm and work their way down, they start slowly and work their way up. “Once it finds that sweet spot—the set point temperature—it’ll go into what I call cruise control. It’s a compressor with a gas pedal,” explains Wagner.

Flash Injection

There are a few different methods manufacturers use to further enhance the capabilities of heat pumps, and one is flash injection technology, sometimes also referred to as enhanced vapour injection. It’s this technology, when combined with inverter compressors, that is allowing heat pumps to perform at much lower temperatures, creating the ‘cold climate’ heat pump category.

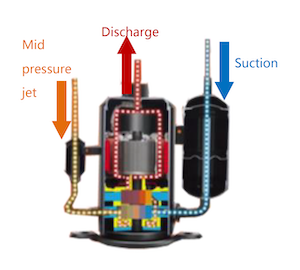

Figure 1.

As Wagner explains: It’s commonly called the two-stage vapour injection compressor. Referring to an image (see Figure 1), he points out the two suction ports and the single discharge. When vapour changes pressure energy is produced, and that’s what is happening here. He explains how that second injection port has a vapour injection valve which, based upon outdoor air temperature and some other criteria, will open and ultimately provide that added heating capacity.

“That’s how we’re getting heat out of outdoor temperatures like -33F (-36C).”

Lived Experience

McTeer has connected a cold climate heat pump to the centrally-ducted air handler in his home in the Ottawa area, and he revealed some ‘balance point’ charts to show the difference between a conventional multi-stage system compared with his inverter-driven cold climate technology.

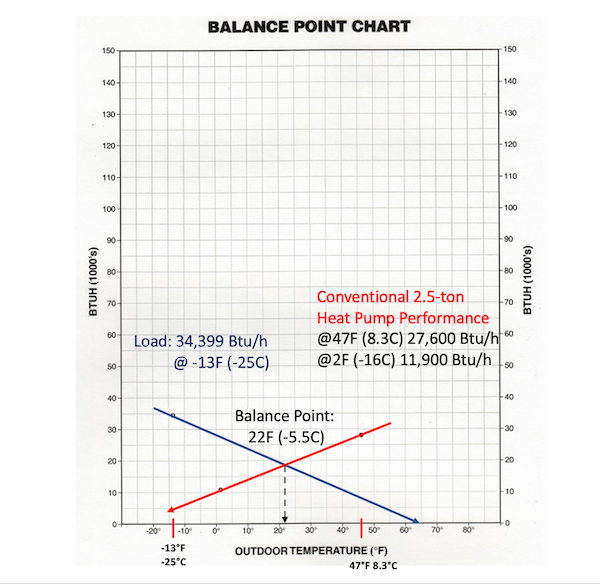

Figure 2a.

“This chart [see Figure 2a, above] is something we used to do in the early days of conventional heat pumps. My outside design temperature is minus -13F (-25C), and the load at design is 34,399 Btu/h.”

So he drew a line from minus -13F (-25C) across and down to 65F (18C), the theoretical point where no heating or cooling is required—that’s the ‘load line.’

Then he created an ‘equipment line’ using data from a conventional two-step heat pump, where at 47F (8.3C) the unit would put out 27,600 Btu/h, and at 2F (-16.6C) its output would be 11,900 Btu/h. The balance point, where the equipment line crosses the load line, is 22F (-5C). That’s the point where second stage is going to call.

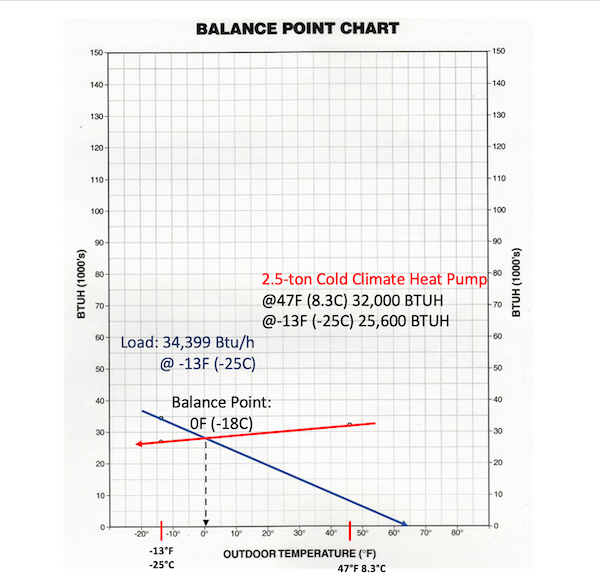

Figure 2b.

Data from McTeer’s own installed 2.5-ton cold climate heat pump [Figure 2b] shows that at 47F (8.3C) it’s producing 32,000 Btu/h, and at -13F (-25C) its output is 25,600 Btu/h. Now the balance point, using the same load and the new equipment line is down to 0F (-18C).

“So at -18C I’m going to get a bit of my back up electric resistance heat coming on to supplement, so both units will be running together,” says McTeer. “We’ve been through two winters now and it’s just been absolutely delightful.”

Multiple Benefits

Among other benefits, Wagner explained how inverter technology actually improves the capacity of multi-zone mini-split systems. Since the inverter compressor matches the load, whichever zones are calling, or not calling, the output of the compressor matches the load at that moment in time.

Also, when looking at different multi-zone possibilities, he insists that contractors don’t just look at model number of the outdoor unit and assume that is the highest output capacity. For example, an 18,000 Btu/h outdoor inverter multi-zone compressor can, in many cases, give you as much as 22,000 or 23,000 Btu/h of cooling and heating.

“So it’s always best to look at the capacity chart, not the model number,” he says.

Today’s cold climate heat pumps are premium products, so cost could be a barrier to acceptance, and McTeer shared other concerns regarding market adoption of the technology.

“If everyone on my street converted to a heat pump like mine tomorrow, there’s not enough electricity on the street to run all those heat pumps and the required electric furnace back up on the coldest days.”

For Wagner, who has been traveling across Canada educating wholesalers and others about heat pump technology, the future looks bright.

“We have gone through a number of winters with the inverter technology, and even with the vapour injection technology, and we are just thrilled to be getting reports from coast to coast, and in northern Canada as well, where systems were performing as designed. The technology is working. It’s tried and true, and it’s nothing to be afraid of at this point.” <>

To re-visit past editions of 30 Mechanical Minutes visit our YouTube channel (@hpacmag).

Here’s the complete episode.