Hybrid mechanical systems: here comes the future

March 23, 2019 | By Ian McTeer

I had not had much to do with the concept of a hybrid anything before landing in the HVAC industry many decades ago. After a few years of learning about disparate topics stretching from gas heating to residential cooling, it was my wife, a green-thumb gardener, who introduced me to hybrid plants in a “by the way” point of interest fashion. She had planted some Hollyhocks next to a Rose of Sharon shrub in our tiny backyard garden. Mother Nature worked her magic giving us a wonderful hybrid Rose of Sharon shrub incorporating its own gentle mauve coloured flowers surrounded by gorgeous red hybrid hollyhock blooms the following growing season. Although the hybrid shrub did not exactly appear on her garden plan that year, the end result made my wife the envy of the neighbourhood.

Thus, a dictionary defines “hybrid” as something “related to or produced from parents of different species, varieties or breeds” such as our Rose of Sharon/Hollyhock shrub. A further definition states a hybrid has “two different types of components performing essentially the same function” such as a hybrid vehicle.

Today, the term is widely used in many fields (perhaps overused), to describe a myriad of technological wonders.

CONVENTIONAL RESIDENTIAL HEAT PUMP

Thanks to the oil embargo put in place against the United States by OPEC in 1973, devices that promised to save on heating and cooling costs for residential consumers proliferated on a grand scale. By the time the AHRI (then known as ARI) had defined the North American climate zones, air source heat pumps started to appear in Canada. That is when, in the early 1980s, I was introduced to the concept of a hybrid heat pump (HHP) sometimes called a dual fuel heat pump. Ideally, an HHP would save energy by utilizing its ability to generate considerably more useful heating watts-out than the watts input required to run the system.

However, as I have said before, HHPs and the companion all-electric heat pumps did not perform well in Climate Region V. I have discussed these issues in previous articles: sizing mistakes, siting errors, ineffective defrost controls and low temperature rise among others. In a hybrid application, there are two control strategies that often get confused:

- Unrestricted mode: in which the indoor thermostat fully controls both the outdoor unit and the indoor unit. Such a method in cold climates is not realistic because at the start of every cycle the thermostat will start the outdoor unit even if it is no longer capable of providing 100 per cent of the heat required. The system will run and run blowing cool air until the thermostat differential is overcome allowing the gas or oil furnace to then take over. The fossil-fuel furnace runs until the thermostat is satisfied only to have the next cycle operate the same way. Only the return of milder weather will allow the system to work at full benefit. Unrestricted mode was not meant for HHPs in cold climates.

- Restricted mode: in which a separate control kit (now typically part of the specialized indoor heat pump thermostat) works in conjunction with an outdoor thermostat to prevent outdoor unit operation below balance point. This control strategy required the contractor to ascertain the heat loss of the building and to plot the performance of his selected equipment on a balance point chart to determine when outdoor unit operation would no longer be viable. The outdoor thermostat would then be set at that temperature. Too often, this temperature was set arbitrarily. Too low a setting causes the customer to experience a situation similar to unrestricted mode–the unit runs long after its full heating capacity has been utilized leaving the customer shivering before a welcome blast of second stage heat finally occurs. Setting the outdoor thermostat too high means the outdoor unit shuts off early leaving the customer to pay for more fossil fuel than expected.

HYBRID CONTROLS HAVE IMPROVED

The days of electro-mechanical HHP controls have long since passed. Modern hybrids utilize electronic comfort controls consisting of a smart room thermostat driven by feedback loops that constantly update room temperature information. Some thermostat algorithms will create control points slightly above and below the desired room temperature set point. Room temperature fluctuations are then monitored between those points. For example, should the room temperature be set at 70F (21C), the algorithm will select 69F (20.5C) and 71F (21.6C) as control points constantly checking for temperature swings between the set point and the control points. Also, the algorithm will monitor how long the room takes to increase or decrease its temperature. By monitoring temperature swings in real time, the controller then makes decisions about which heating or cooling unit should be started, in what stage and for how long.

Another critical component of hybrid control is the outdoor temperature sensor (ODS). Long known on the hydronic side of the HVAC industry as an outdoor reset control, an ODS helps the smart thermostat to adjust the output of a modulating or multi-stage heating device to more closely match building heat loss. Outdoor sensors are very accurate providing temperature data within a +/- 1 per cent variance. Thus, the sensor must not be influenced by direct sunlight or other sources of heat. Depending on the manufacturer, a failed ODS might simply generate a non-critical error alert (similar to the automotive “service engine soon” light) or possibly force the system into an emergency heat mode. Thus, the ODS has become a very important hybrid component.

HYBRID IS THE NEW CONVENTIONAL

When I first started in HVAC, a conventional residential forced warm air system (FWA) or boiler did one thing: heat. Many of the older oil-fired FWAs I encountered worked very well. Typically consisting of an easily accessible centrally located furnace, beautifully laid-out and properly sized ductwork, these single zone systems provide quiet, even-heating. As the post-war housing boom expanded exponentially, FWA heating became more of a nuisance for builders having to accommodate duct systems and provide chimney chases. FWA systems occupied too much space in the “unfinished recreation room.” Efficient, comfortable HVAC became the exception rather than the rule.

One could argue that the first act of residential hybridization saw the addition of central air conditioning to FWAs meant strictly for heating. Then, the first iteration air source heat pumps (ASHP), totally unprepared for cold climates as it turned out, introduced the concept of hybrid HVAC allegedly under the guise of saving energy. As I’ve mentioned before, far too many FWA’s struggled to simply provide decent heating never mind saving extra energy. Lost in the early hybrid ASHP invasion was the notion of comfort. The glossy brochures showed mom and dad and the kids happily frolicking in the family room, yet there was an entirely different comfort story going on upstairs in January and July.

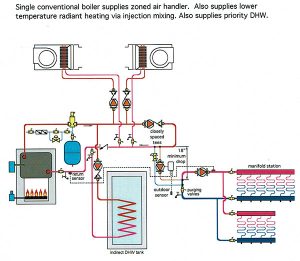

Conceptual drawing from John Siegenthaler’s “Hydronic Basics” illustrates one potential residential hybridization.

Therefore, by my definition, a hybrid HVAC system uses one or more sources of heat (or cooling) to provide independent space comfort conditioning and can be combined with accessory heating capabilities. Here are but a few examples:

1. A condensing boiler supplying a priority indirect domestic hot water tank and two zoned air handlers. Add some injection mixing to supply lower temperature radiant heating and maybe include some other accessories like panel heaters or even garage floor warming. Better yet, send the heated water to a hot water coil incorporated into a small duct high velocity system. Utilizing the principle of aspiration, rooms so serviced will have superior air mixing throughout the year providing ideal comfort.

(Above and below) A multi-function VS air handler with a hot water coil and heat pump coil installed.

2. Provide a zoned FWA system consisting of proprietary zone dampers and controls. Use a matching VRF or two-stage air source heat pump (ASHP) linked to a variable speed modulating gas furnace or air handler with electric heat. Design the system for new construction or a major house renovation using the methods outlined in the Air Conditioning Contractors of America (ACCA) Manual Zr. Test, adjust and balance the system for best results.

3. A multi zone, cold climate air source heat pump (ccASHP) for retrofit applications in which an existing, underperforming FWA system cannot be easily renovated. Hybridize an existing viable furnace for back-up and emergency heating only. Houses heated primarily with baseboard electric heaters can utilize ductless system hybrids capable of controlling baseboard operation when necessary.

4. With the focus now on tighter house construction (0.5 ACH) and Net Zero energy consumption, the ccASHP hybrid system seems ready to dominate the residential new construction market. With the ability to provide simultaneous heating and cooling combined with many air handling options like high wall fan coils, recessed ceiling units, low static ducted air handlers, exposed and concealed low-wall units and a more conventional vertical fan coil, heating contractors have nearly unlimited ways of providing comfort and efficiency.

4. With the focus now on tighter house construction (0.5 ACH) and Net Zero energy consumption, the ccASHP hybrid system seems ready to dominate the residential new construction market. With the ability to provide simultaneous heating and cooling combined with many air handling options like high wall fan coils, recessed ceiling units, low static ducted air handlers, exposed and concealed low-wall units and a more conventional vertical fan coil, heating contractors have nearly unlimited ways of providing comfort and efficiency.

For several decades prior to 1973, energy was fairly inexpensive and relatively abundant. When energy became expensive, seemingly overnight, counter remedies seemed too often to be hit or miss in so many ways:

- Smaller, lighter cars, allegedly more fuel efficient, rusted-out quickly when exposed to salted roadways

- Emission controls mandated for all cars caused many to guzzle even more fuel

- Early so-called high efficiency gas furnaces did not have secondary heat exchangers. Too much heat extraction (some ran at 88 per cent AFUE) caused condensation in the primary heat exchanger or in the vent connector leading to equipment failures.

Initial attempts to produce 90 per cent AFUE condensing gas furnaces revealed gaps in metallurgical knowledge. Secondary heat exchangers made out of mild stainless steel rotted-out in the presence of acidic condensate, typically in less than five years. Metallic draft inducer housings, even those with epoxy coatings failed routinely.

Far too many hybrid ASHPs rarely worked properly having never been designed for a northern climate. Many ASHPs were simply converted to cooling-only operation allowing the primary heating source to do all the heating heavy lifting.

Decades of technological innovation has solved many such problems. While house builders could have sealed-up and better insulated their products back in the ’80s, the technology needed to deal with excess moisture has only really been available and put to good use in the last decade or so. All those old cars and all those clunky old furnaces are gone now; however, the houses still exist. Many, many of them have been retrofitted or renovated, perhaps more than once.

The fact remains that unless the heating system fell into the hands of a qualified heating contractor, the comfort and efficiency equation is still unbalanced in so many Canadian houses. A hybrid system, in my opinion, promises to deliver the necessary and very comforting Btus to where they are needed in a timely fashion. Again, hybrid is the new conventional. <>

Ian McTeer is an HVAC consultant with 35 years experience in the industry. He was most recently a field rep for Trane Canada DSO. McTeer is a refrigeration mechanic and Class 1 Gas technician.