Copeland Oil-Free Centrifugal Compressor for Chillers

March 13, 2024 | By HPAC Magazine

Frictionless, oil-free compression technology offering efficient performance for air- and water-cooled chiller applications.

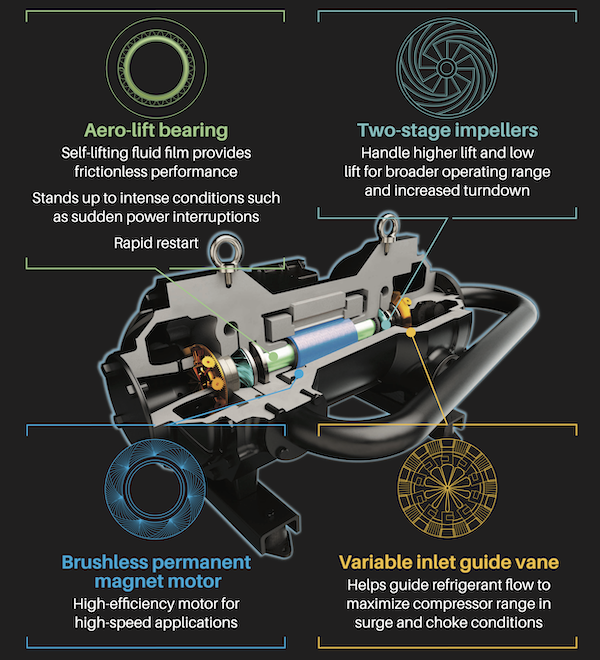

Copeland has introduced its new oil-free centrifugal compressor with frictionless Aero-lift bearing technology. Engineered to be a worry-free alternative to existing magnetic levitation bearing and refrigerant-lubricated ceramic compression technology, the Copeland oil-free centrifugal compressor delivers high-lift performance for demanding chiller applications.

The new compressor will help original equipment manufacturers (OEMs) simplify the application of oil-free compression technologies while meeting requirements for high efficiency, system design flexibility, and compatibility with lower global warming potential (GWP) refrigerants.

Designed for mission-critical data centre, health care, large chiller, and heat recovery applications, the oil-free centrifugal compressor can enhance air- and water-cooled chiller performance, and the oil-free centrifugal compressor platform is being developed for the 50- to 200-ton capacity range and is optimized for use with lower-GWP A2L and A1 refrigerants such as R-1234ze, R-515B and R-513A.

The Aero-lift bearing technology enables the compressor shaft to self-levitate and operate independently — without friction or reliance on electromagnetics, complex controls, or proximity sensors, which are required in today’s oil-free magnetic levitation bearing compressors.

The oil-free centrifugal compressor is decoupled from controls and variable frequency drive (VFD) — helping OEMs to design systems capable of withstanding harsh, humid application environments that could potentially damage controls.