Air-to-Water Heat Pumps Today

November 14, 2023 | By HPAC Magazine

In this recent edition of HPAC Magazine's 30 Mechanical Minutes, John Siegenthaler discusses the fundamentals of air-to-water heat pump technology and goes over some system design considerations.

HPAC editor Doug Picklyk (left) and John Siegenthaler talk air-to-water heat pump technology in this edition of 30 Mechanical Minutes.

The latest installment of HPAC magazine’s 30 Mechanical Minutes, the free webinar series, took place August 23rd and focused on air-to-water heat pumps: how they work, who’s making them and some key installation considerations.

In this episode, HPAC editor Doug Picklyk was joined by regular contributor and hydronics expert John Siegenthaler. This edition was sponsored by Aermec, manufacturers of air-to-water heat pumps for commercial and residential applications.

The worldwide push towards decarbonization and electrification is leading the hydronics industry away from gas-fired boilers and towards electrically powered heat pumps, both geothermal solutions which can carry a large install cost because of the required geothermal loops, and the more approachable air-to-water heat pumps.

Siegenthaler foresees that air-to-water heat pumps are definitely going to be a growing market across North America, noting that it’s already a very large market globally, with about 4 million a year going into traditional hydronics markets in Europe and Asia.

In explaining the basics of how air-to-water heat pumps operate, Siegenthaler drew the comparison to a ductless mini split, which is a heat pump that absorbs heat from outside air, but instead of blowing air into a building, an air-to-water system distributes that heat through a heat exchanger to a hydronic distribution system.

TWO TYPES

There are a two different ‘flavours’ of air-to-water heat pumps. One style is called a ‘monoblock,’ or a self-contained unit. It is factory charged with refrigerant.

“The installer is going to set that on some type of a pad or a mounting frame. They’re going to connect two water pipes to it and an electrical harness, but typically there is no need to adjust the refrigerant charge in it,” explains Siegenthaler.

He suggests that this will probably be the dominant configuration, at least initially, as air-to-water heat pumps gain market share in North America.

In monobloc systems the refrigerant is contained in the outdoor unit and water solution runs from the outdoor unit to inside. As Siegenthaler explains, typically in cold climates most manufacturers are going to insist on using antifreeze in the water, typically a mixture of propylene glycol and water. “If there is a prolonged power outage, and it’s below freezing, any water in an outdoor unit it could freeze and damage the unit.”

The other configuration is a “split’ system, similar to common central air conditioning systems or even a ductless mini split. There is the outdoor unit and an indoor unit connected with refrigerant lines. The refrigerant flows from the outdoor unit through the indoor unit where it transfers heat to water.

He says the installation of this type of system requires some basic refrigeration tools and skills, like knowing how to connect the line set, how to do a pressure test, or how to pull a vacuum.

He listed 10 different brands that manufacture and sell air-to-water heat pumps in North America, either monobloc or split systems, including three Canadian brands (Arctic Heat Pumps, Nordic Heat Pumps and ThermAtlantic). He also notes five other manufacturers that are anticipated to hit the market soon in this category.

“I do want to stress; there is product availability,” says Siegenthaler. “This is not something we’re waiting for. If you want to go out and install one of these systems tomorrow you have several brands, and within each brand you’ve got different capacity ranges to choose from today.”

He estimates that within the next couple of years we’re going to see more companies getting into the air-to-water heat pump market with offerings in North America, including brand names more familiar to those in the traditional boiler market and the more traditional furnace market.

COLD CLIMATE CONCERNS

Hydronics pros are concerned about the heating capacity of a heat pump when compared with a gas-fired boiler. And Siegenthaler explains, that as it gets colder outside any air source heat pump decreases in its heating output, so the Btu/h it can generate goes down when you need heat the most.

He presented a graph showing that heating capacity is also a function of the water temperature we require the machine to output. The lower the water temperature the heat pump outputs the higher its heating capacity.

Coefficient of performance, COP, is the ratio of the heat output divided by the power input used to generate that heat. As it gets colder, the COP (or efficiency) goes down, and as the water temperature that the unit is operating at (supply temp.) increases, the COP also goes down.

So, for Siegenthaler, the takeaway is that the best performance is going to be with low temperature hydronic distribution systems like radiant slabs, large panel radiators and fan coils that can be sized for temperatures of 120F (49C) or less. He uses that number as a typical guideline.

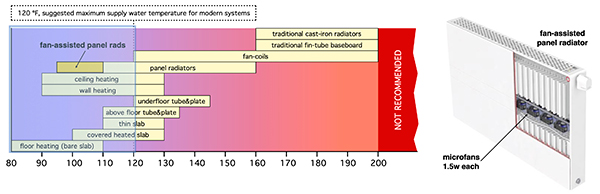

Figure 1.

Showing a bar graph (see Figure 1), he displays typical ranges of water temperature for different hydronic heat emitters, and on the left, in the purple, he’s drawn a line at 120F.

From this diagram he shows how several types of radiant systems including floor heating, wall heating, ceiling heating as well as panel radiators can be effective with low temperature water.

Siegenthaler mentioned a job he was involved with last winter that used panel radiators supplied from an air-to-water heat pump. “We’re able to heat the house with 90F water, and it’s because the panel radiators have been sized for those low water temperatures.”

But he also says, “Don’t give up on air-to-water heat pumps even if you have a hydronic baseboard system, because you will still get partial output, and in many climates you can get three quarters or more of the seasonal heating energy from the heat pump.”

Radiant ceilings

He’s also a proponent of non-typical solutions like radiant ceilings and walls. “I would urge people to look at these.”

Using radiant ceilings as an example, he says that at 110F degree average water temperature he can get about 28 Btu/h per sq. ft. “It comes up to temperature quickly, and it’s adaptable to radiant cooling down the road.”

He also showed examples of radiant walls, the same construction principles as the ceilings just turned 90 degrees. “You really don’t see them much, but they’re a little higher output than a radiant ceiling because there is a little bit better convection on a vertical surface.”

And modern panel radiators are also a great option, with several brands available now in North America.

“They can be sized around relatively low water temperatures, I’d say anywhere from 100F to maybe 120F at design load, and they can be equipped with a thermostatic radiator valve, so the homeowner can have room by room zoning with no batteries, no wires, no apps. Just a very simple little turn of a knob.”

Dual Fuel

Instead of direct replacements, he foresees a future with homeowners keeping their boilers along with an electric air-to-water heat pump.

“Dual fuel has a number of really good points to it, especially if it’s a retrofit,” says Siegenthaler. “If you’re going into a house or commercial building that has a boiler that has some life left in it, don’t tear it out. Use it as the backup and as the supplemental heater.”

“One of the nice things about a fossil fuel boiler is you can run it on a very small generator. So, on the occasion where you have a power outage, while it is possible to run a heat pump on a backup generator, it has to be a fairly large generator. Probably a minimum 5,000-Watt generator on an average house.

“Whereas a boiler, the burner on an oil burner needs about 400 watts of power, and the circulators are low power. So, with a relatively small portable generator you could keep the heat on in the building using the boiler.”

He says another nice thing about dual fuel, is that it sets up scenarios favourable to both electric utilities and customers. “Think about off peak rates where the heat pump could operate on the lowest cost electricity, and then perhaps the fossil fuel boiler could operate when electricity is at peak price. I think that opens up a lot of possibilities.”

There were many great questions asked by the live audience.

To view the entire webinar, see below (and past editions of 30 Mechanical Minutes also available on the HPAC YouTube channel @hpacmag. <>