Chump Change: Distribution Efficiency Advantage of Hydronics

November 20, 2023 | By John Siegenthaler

John Siegenthaler goes over how the low cost of operating a well-designed distribution system is an often-overlooked efficiency advantage of hydronics.

(Getty Images/DeepBlue4You)

Hydronic heating professionals often promote the concept that current generation modulating and condensing (mod/con) boilers can operate with annual fuel utilization efficiencies (AFUEs) in the range of +/- 95%. And professionals who install geothermal water-to-water heat pumps often boast that their equipment is capable of seasonal average coefficients of performance (COPs) in the range of 3.0 to perhaps 4.0. These performance numbers are possible given the right equipment, the right application, and specific definitions for thermal efficiency and COP.

However, most of those same hydronic pros don’t bother to describe how a well-designed and properly installed hydronic heating system has a distribution efficiency much higher than that of either a forced air system or a system that moves heat through a building using refrigerant (e.g., ductless mini-split heat pumps or VRF systems).

Beyond Thermal Performance Acronyms

For a heating system to truly be best-in-class it needs a high efficiency heat source and the ability to move heat through a building using minimal amounts of electrical energy.

The latter criteria can be quantified using the concept of distribution efficiency, as defined by Formula 1:

Distribution efficiency has nothing to do with converting electricity or any type of fuel into heat. It also has nothing to do with the system’s heat source. Instead, it describes how many Btu/h of heat the distribution system can move from the heat source to the heat emitters for each watt of electrical power supplied to operate that distribution system.

The more heat the distribution system can deliver per watt of electrical power input the higher its distribution efficiency.

To show how wide the gap is between two contemporary systems consider a relatively simple hydronic heating distribution system, one using currently available off-the-shelf hardware compared to a forced air distribution system on a state-of-the-art geothermal heat pump.

The hydronic system assumes a building with a design heating load of 30,000 Btu/h. The building will be heated using eight identical panel radiators measuring 24-in. high by 72-in. long by 4-in. thick. Figure 1 (below) shows an example of one such radiator.

Figure 1. Example panel radiator with thermostatic radiator valve.

These relatively large panels were selected so the building’s design heating load could be met using an average water temperature of only 110F and a 20F temperature drop (e.g., supply water at 120F and return water at 100F). That temperature makes the system well suited for mod/con boilers, geothermal water-to-water heat pumps, and air-to-water heat pumps.

Those eight radiators, operating under these conditions, put out a total of 30,800 Btu/h, just a bit more than the building’s design load.

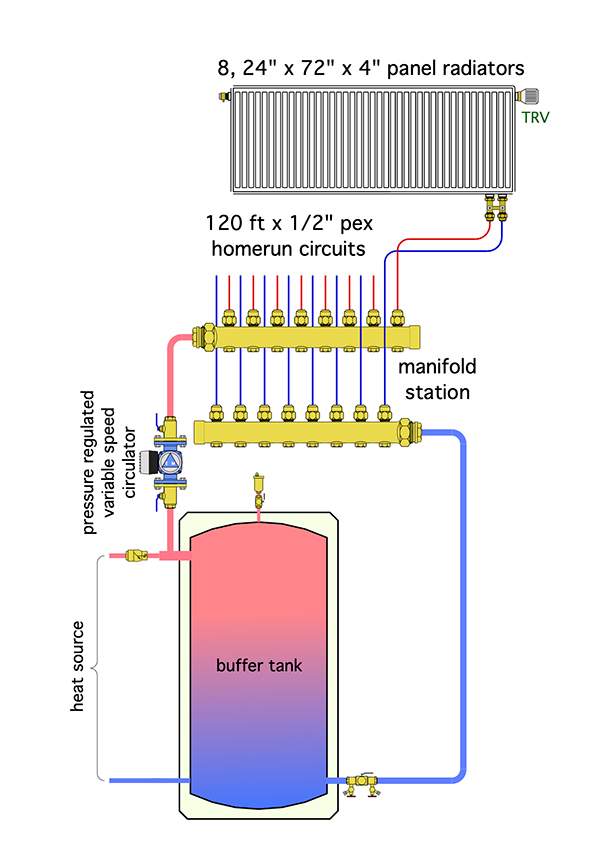

The piping for this system is very simple, and it is shown in Figure 2 (below).

Figure 2.

The system uses thermostatic radiator valves, which allow each radiator to function as an independent zone. Each room can individually respond to internal heat gains, temperature setbacks, and personal comfort preferences.

Each radiator is connected to a manifold station by 120 feet of ½-in. PEX tubing (60 feet on supply plus 60 feet on return). The result is a simple homerun distribution system.

A buffer tank is shown between the heat source and distribution system. Its purpose is to prevent heat source short cycling given the relatively low design load combined with a highly zoned distribution system.

From the standpoint of distribution efficiency, the heat source that warms the buffer tank is irrelevant. It’s the hydraulics of the distribution system and those of the variable speed pressure-regulated circulator that matter.

The total system flow rate required to deliver 30,800 Btu/h with a 20F temperature drop is only 3.1 gallons per minute (gpm). This divides up equally among the panels, so each circuit only requires 0.39 gpm.

The combined head loss of the 120 feet of PEX tubing and the panel radiator at this small flow rate is only about 4.2 feet of head. Let’s add another 10% to this head loss to account for some head loss in the short 1-in. piping connecting the manifold station to the buffer tank.

The circulator duty point in this system is therefore 3 gpm at 4.6 feet of head.

Paltry Power

The flow rate and head requirement can be used to estimate the electrical power input to a circulator. To be conservative I assumed a modern ECM circulator with a wire-to-water efficiency of 25% at the calculated duty point.

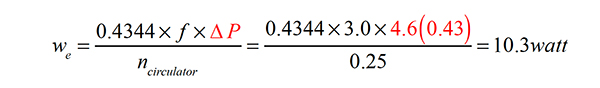

The estimated electrical input to the circulator can be calculated using Formula 2:

Where:

We = estimated electrical input wattage to circulator (watts)

f = flow rate (gpm)

∆P = pressure differential across the circulator (psi)

Ncirculator = wire-to-water efficiency of circulator (decimal percent)

0.4334 = unit conversion factor

The multiplication of 4.6 x (0.43) represents the head requirement converted to differential pressure (e.g., ∆P), which is necessary to make Formula 2 valid.

If a circulator operated continuously for 24 hours, at this power input, and at a location where electricity costs $0.20 per kWh, the total daily operating cost would be 5 cents!

If the circulator operated continuously throughout a heating season lasting 3,500 hours, at the same input wattage, the total operating cost would be about $7.30. I suspect that most homeowners could work that into their budget.

A few years ago, you would not be able to find a circulator that could operate at such low power. Today there are several circulators on the North American market that can operate in the nominal 10 Watt power range. One example is shown in Figure 3 (below).

Figure 3. One example of a low-power modern circulator available today.

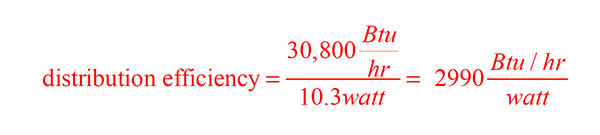

The distribution efficiency of the example hydronic distribution system can be calculated using Formula 1:

An Interesting Comparison

So how does a distribution efficiency of 2,990 Btu/hr/watt rank relative to that of other systems?

To put this number in perspective, let’s compare it to the distribution efficiency of a modern geothermal water-to-air heat pump with a variable speed ECM blower motor.

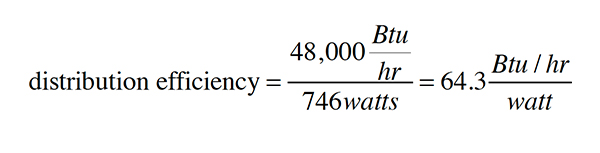

One manufacturer lists the wattage of an ECM blower on a nominal 4-ton (48,000 Btu/h) rated water-to-air heat pump, at full speed, as 746 Watts. Assuming the heat pump delivers 48,000 Btu/h using 746 Watts input to the blower, its distribution efficiency would be:

The two calculated distribution efficiencies can be compared by making the numbers into a ratio: 2990/64.3= 46.5.

This means that this hydronic system is delivering just over 46 times as much heat to the distribution system, per Watt of electrical input energy, compared to the heat pump using forced air distribution.

The inverse of that ratio, 64.3/2990 = 0.0215, or about 2.2%, implies that the hydronic system delivers heat to the building using only about 2.2% of the electrical input power required by the referenced forced air system.

Either way you look at it, the hydronic system in this comparison is far more efficient when it comes to delivering, heat.

This is not meant as a “put down” on the geothermal heat pump used in the comparison. That heat pump’s thermal efficiency could be excellent (perhaps a COP of 4.0 or more). However, because the heat pump delivers heat using air rather than water its distribution efficiency is very low in comparison to the hydronic system.

A Story Worth Telling

The concept of high distribution efficiency should be a starting point—rather than an afterthought—when discussing the advantages of a modern hydronic systems.

Especially in light of modern low energy and net zero energy buildings, our industry needs to get this message to trade allies like architects and engineers involved with low energy or net-zero buildings, energy auditors, professionals involved in thermally based renewable energy heat sources, and regulators who determine which HVAC technologies are incentivized through government programs.

That’s not going to happen if our industry isn’t proactive.

There are lots of technically competent decision makers who have never heard about distribution efficiency.

I suspect many of them would embrace the concept based on real comparisons.

It’s time we show them what’s possible. <>

John Siegenthaler, P.E., has over 40 years of experience designing modern hydronic heating systems and is the author of Modern Hydronic Heating (4th edition) and Heating with Renewable Energy (visit

John Siegenthaler, P.E., has over 40 years of experience designing modern hydronic heating systems and is the author of Modern Hydronic Heating (4th edition) and Heating with Renewable Energy (visit