From Steam to Sustainable

September 13, 2023 | By Jeff Flannery

Packaged energy transfer stations ease the transition for Sheridan College’s district energy system.

The district energy supply system at Sheridan College in Oakville, Ont.

Creating a sustainable energy system to heat, cool and power an entire college campus is no easy feat. In 2013, when Sheridan College in Oakville, Ont. launched its Energy and Climate Master Plan, with the goal of lowering campus energy and greenhouse gas emissions by half, they realized that they would need to transform their heating and cooling system.

The school looked to the Trias Energetica model, first developed in 1979, as a guide to developing a sustainable energy system, integrating heating and cooling functions and recovering energy that might otherwise be wasted.

“We wanted to position Sheridan as a role model on sustainability and follow best practices. This ties into our educational mission as well,” says Herbert Sinnock, Sheridan’s director of sustainability.

After an evaluation of the HVAC infrastructure in existing campus buildings, the college realized that the most effective way to make its heating and cooling operations more efficient was to install an entirely new system, using a district energy model, starting with its Trafalgar Campus in Oakville.

Implementing District Energy

Sheridan began constructing its third-generation district energy system in the summer of 2016, burying 3.5 km of pre-insulated pipes that carry pressurized hot water across the campus from a central plant to every building.

Sinnock notes that the pipe network is not installed very deep in the ground, which made it quick and easy to install. Modern pre-insulated pipe systems integrate leak detection, helping operations teams quickly identify any problems to ensure the system will continue to operate at peak efficiency.

Reciprocating heat and power engines, installed in 2017 and 2018, generate baseload heating for the system along with a modest amount of electricity. Supplemental boilers provide additional temperature lift on very cold days.

Centralized delivery uses less energy than a distributed system with separate boilers in each building. In the summer, the engines’ heat can be sent to an absorption chiller that feeds the chilled water network to several campus buildings.

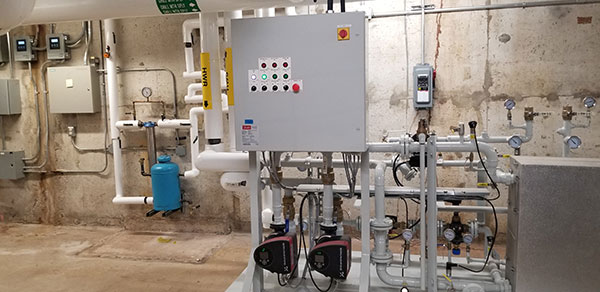

At each building, heat is transferred from the system’s primary loop to each building’s secondary heating system through a Danfoss energy transfer station (ETS). The ETS is an interconnected system of heat exchangers, valves, pumps, programmable controller, metering and piping that draws heat from the primary loop of pipes outside each building to control and feed the building’s secondary heat network.

An energy transfer station in each building draws heat from the primary loop outside to feed each building’s secondary heating loop.

A pressure-independent control valve on the primary side of the ETS ensures the heat exchanger operates efficiently, using an outdoor temperature sensor to modulate the heat transfer process for each building while allowing each building’s heating system to operate independently.

The ETS is a key component of the district energy system because it contains automated controls which provide continuous digital metering and can monitor and adjust to the demands of the building, controlling temperatures and working to maximize the combined efficiency of the primary loop and the buildings.

A Customized Approach

“We wanted to acquire the product from a company with an established track record of installing these devices. We were aware that Danfoss had a rich history of selling ETS outside of North America,” said Sinnock. “We liked that the stations could be factory built, customized and programmed to match our facility, then delivered fully-assembled and ready to operate on day one.”

In 2019, Sheridan began a three-year project to decommission a nearly 50-year-old steam plant serving six of its Oakville buildings, replacing it with the new hot water district heating system capable of heating the entire campus.

A steam-to-hot-water conversion requires replacement of all steam-generating equipment with a completely new system. That means that the campus buildings would potentially be without heat during the installation period. Sinnock noted that while it was a challenge to coordinate both contractor schedules and the school’s academic calendar, the installation went smoothly.

Because each ETS arrives ready for start-up with factory-configured and pre-tested controls, they are able to control the heat exchange between the primary loop and the building upon first start. This meant that the period when buildings would be without heat could be minimized and multiple buildings could make the transition to the new district energy system in quick succession.

Each ETS includes an interconnected system of heat exchangers, valves, pumps, programmable controller, metering and piping.

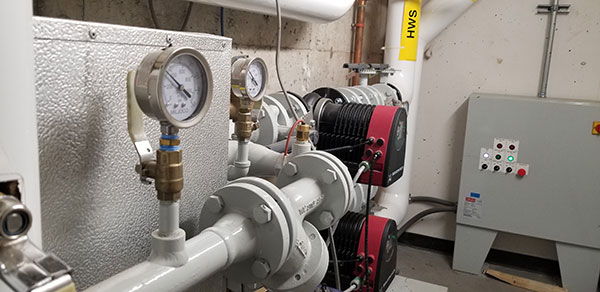

The ability to customize the pipe network on each ETS to facilitate connection to the unique conditions in each mechanical room minimized delays in connecting the new equipment. It also enabled quick movement of complete energy transfer stations into the tight spaces of the existing system.

“It only took a couple of hours per unit to start up the system,” said Sinnock. “The pre-programming and pre-testing helped make the transition seamless.”

Leading the Community

Ultimately, the increased efficiency and decreased system operating temperature will lower the college’s carbon emissions, with the potential to contribute to decarbonization throughout the community.

Sheridan’s district heating system creates an energy network, where heat can not only be recovered and reused within campus buildings but can be recovered and supplied to buildings in the larger surrounding community.

At some point, Sinnock envisions connecting the college’s energy system to a larger municipal district energy network and sharing heat with multiple buildings in the community.

The pipe network on each ETS was configured to the unique conditions in each mechanical room allowing them to fit into the tight spaces of the existing system.

“We are excited to integrate and maximize our district energy architecture,” said Sinnock. For example, a local ice rink would be able to provide excess heat, as can the college’s glass-blowing studio.

“We wanted to be a community leader and educate others about district energy,” said Michelle McCollum, associate vice president of facilities and sustainable infrastructure at Sheridan.

“When people see a district energy network in action, it becomes real. We are able to help make changes in community energy plans and embed a culture of sustainability. Our district energy system demonstrates that we live the words we are saying.”

She noted that a recent employee survey indicated that 95% of Sheridan employees were aware of the college’s efforts in sustainability and energy efficiency.

Achieving Energy Reductions

Sinnock admitted that reducing carbon emissions in heating is challenging, as is achieving a return on investment in system upgrades.

Fortunately, Sheridan’s leadership and Board of Governors saw the value and supported the project. Prior to the switch to district energy, the college’s steam plant was losing about 65% of the heat it generated. Following the conversion to the more efficient hot water system, natural gas consumption was reduced by 20%, which equates to an annual carbon reduction of 530 metric tons.

“We expect to see even more reductions in energy use and costs as we attach more buildings to this system,” says Sinnock. <>