Outdoor reset

February 24, 2020 | By Robert Waters

The under-utilized king of hydronic controls.

Outdoor reset control technology for hydronic heating systems has been around for decades. I learned about the technology when I started working for CanaPex (predecessor of Uponor) in the late 80’s. I was designing hydronic radiant floor heating systems and was taught to recommend a Tekmar four-way mixing valve with motorized actuator and outdoor reset control for every system.

Later, when I moved to Viessmann in the mid 90’s, I learned about the Trimatik-MC, the Viessmann boiler control system that combines separate outdoor reset controls for both the boiler and the system via motorized mixing valve. Both of these European-based controls were examples of the rapidly growing market for digital outdoor reset control technology.

Outdoor reset control has been mandated for both new and existing boilers in many European countries since the 1990’s. The digital control market certainly has changed and grown significantly since those early days of my career, but the benefits that outdoor reset technology provides are still very much the same; namely reduced energy use and cost while improving occupant comfort.

You would certainly expect a very mature and established technology like this, with such great benefits, to be widely used for all hydronic heating systems. However, based on my discussions with several industry veterans about the current usage rate of outdoor reset controls, this is not the case.

I was told that outdoor reset controls are still only being used sporadically on residential hot water boiler installations. They are more common in commercial applications where engineers and owners have recognized the significant energy, cost savings and comfort level increases that can be achieved.

This control technology is especially important and timely with new pending NRCan efficiency regulations. As most may already know, NRCan Amendment 15 regulations that just passed into law last year will require all residential boilers <300 MBH to have an annualized fuel utilization efficiency (AFUE) ≥ 90% in 2023 (this means only condensing appliances). This regulation will also require that all residential boilers be equipped with an automatic water temperature adjustment device and must not be able to operate without the device.

Outdoor temperature reset controls, also referred to as weather responsive controls, work for both non-condensing and condensing boilers. They can also be used with heat pumps or biomass hydronic systems by controlling the temperature in the buffer storage tank.

As mentioned, outdoor reset controls provide two great benefits: 1) a dramatic reduction in energy use and cost, and 2) an increase in occupant comfort.

Energy Savings

The energy savings result from the fact that the efficiency of any hydronic heat source is always higher when operating at a lower water temperature. This is due to lower stack temperatures, lower standby heat loss, and with condensing boilers, higher amounts of flue gas condensation. Another efficiency factor that also comes into play is that a boiler will be less likely to short cycle on and off in warmer times of the heating season when it is controlled with outdoor reset.

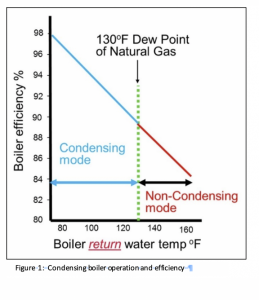

For any gas-fired condensing boiler the operating efficiency will vary in the range of 85% to 98% depending on the water temperature it is operated at (see figure 1).

Many are not aware of this efficiency range because they only look at the AFUE efficiency rating of the boiler. While a condensing boiler may have an AFUE rating of 95%, this rating was established in a test lab with a constant 140F supply temperature. If the boiler is operated in the real world, with a constant high temperature set point of 180F all heating season, it will very rarely condense and likely only have an efficiency in the 85% range.

However, if an outdoor reset control is used the supply water temperature is modulated all winter increasing the efficiency of the appliance in the shoulder seasons providing typical energy savings of 5 to 30%. They are also likely to extend the boiler lifespan by minimizing short cycling.

Enhanced Comfort

On the other hand, outdoor reset controls provide great energy savings while at the same time providing a more comfortable living environment for the building occupants. This is primarily achieved by eliminating the dramatic temperature swings that inevitably occur in any home whose heating boiler is operated at the same water temperature all year long. In order to provide consistent and even indoor temperatures, the heat supplied to the building must equal the heat loss from the building. The biggest factor affecting how much heat a building requires is the outdoor temperature.

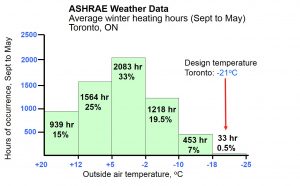

Even in a well-insulated building heat loss increases as the outdoor temperature falls. A hydronic heat source must be set to the highest water temperature setting that will satisfy the coldest day of the winter (design conditions). Design conditions however occur for a very small number of hours per year (less than 5% of the entire heating season: see ASHRAE data), so for the vast majority of the heating season the heat source will be operated at a much higher temperature than is required to meet the load. So what happens when the outdoor temperature is warmer in the fall and spring? At these times the system inevitably overheats the building, creating temperature swings and poor control for the occupants. Overheating will be especially noticeable in high mass hydronic systems such as those with cast-iron radiators and radiant floor systems. In commercial or apartment buildings, where occupants do not directly pay for heating bills, energy use and costs increase even more as occupants open windows to compensate for overheating conditions.

By continuously adjusting the system supply water temperature with an outdoor reset control the hydronic system is able to more closely match the exact heating requirements of the building at all times. The results are more consistent, comfortable space temperatures throughout the entire heating season. An added benefit in homes with fin-tube baseboard systems is a minimization of ticking expansion noises in baseboards by preventing large temperature swings.

How It Works

Outdoor reset works by utilizing an outdoor temperature sensor mounted on the building’s exterior, ideally on the north wall and located away from anything that can give it a false reading such as a dryer or ventilation exhaust vent.

This electronic ambient air sensor actively monitors the outdoor temperature, and based on its reading a microprocessor calculates the heating demand and adjusts the output water temperature of the boiler accordingly. This results in the boiler only running as hot as necessary to achieve the desired indoor temperature.

There are two major categories of outdoor reset control; one being direct boiler reset control and the other being mixing reset control. Some controls will incorporate both boiler reset and mixing reset into one package. A mixing reset control utilizes either a motorized mixing valve or an injection pump to provide a mixed supply water temperature to an individual heating circuit.

Hybrid hydronic systems that have radiant floor heating (RFH) and fan-coil heating are the most common type of system that requires multiple supply water temperatures. For these systems the boiler reset control will provide a higher temperature to the fan coil circuit, and the mixing reset circuit provides a lower temperature to the RFH circuit.

There are many manufacturers today that provide both boiler and system outdoor reset controls. Most controls combine many other features and control capability such as multiple boiler control, wireless outdoor sensors, Wi-Fi connectability, and room temperature feedback. Many condensing boiler manufacturers now integrate the outdoor reset control directly into the boiler so there is no extra added cost.

Set Up

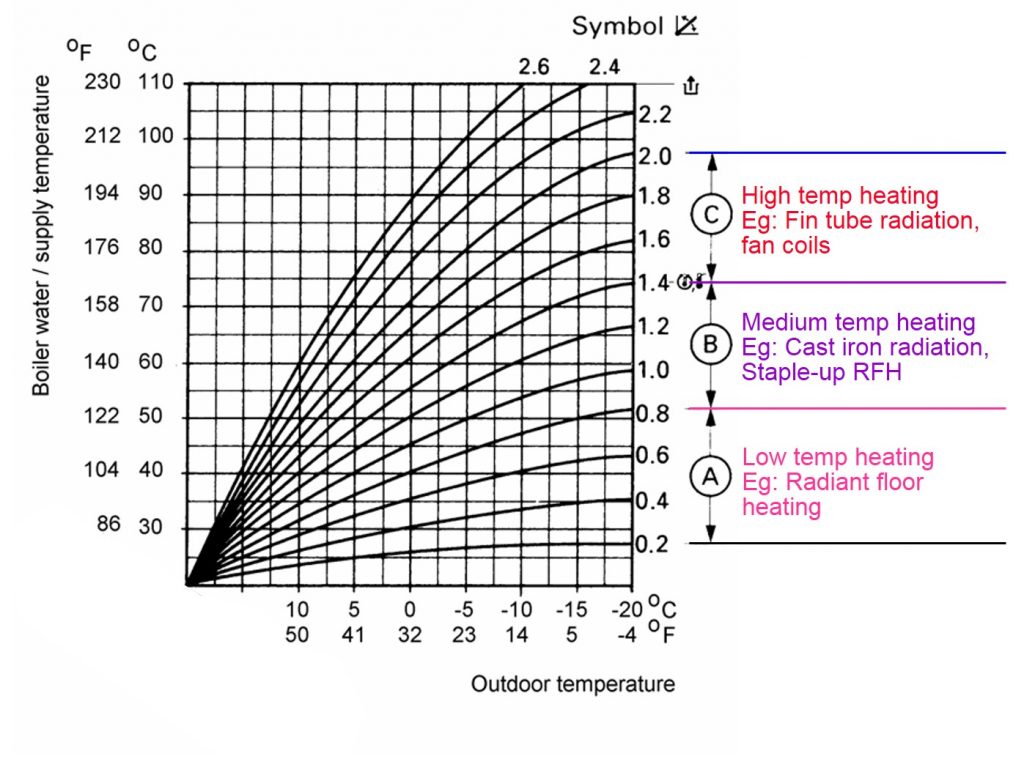

Outdoor reset controls must be set up and calibrated at the time of installation to meet the jobsite specific system requirements. The primary adjustment for any outdoor reset control is the heating curve setting. This setting determines what the maximum supply water temperature will be on the coldest day, and what the lowest supply temperature will be on the warmest day.

The heating curve is determined primarily by the type of heat emitter used in the system.

The control may come with a factory defaulted heating curve, but this will not meet the requirements of all types of systems. Different heat emitters such as high mass radiant floor, cast-iron radiator, and fin-tube will all require unique settings. When using a non-condensing boiler the minimum supply temperature must be set high enough to avoid flue gas condensation in the boiler and chimney (usually a minimum supply temperature of about 140-150F).

Other adjustments such as parallel shift, warm weather shut down (WWSD), and desired indoor temperature may also need to be adjusted.

I do not have space in this article to get into the fine details of setting up an outdoor reset control, but there are many sources for those who want more information. Most manufacturers and distributors of hydronic equipment offer training and advice on how to do this properly, so reach out if you need help.

All of these adjustments must be done by the installing contractor at the jobsite, and I believe the lack of understanding of these settings is one of the primary reasons why some shy away from using outdoor reset controls.

Underused

In commercial hydronic systems outdoor reset control technology is being used extensively because it makes sense financially. Designers and building owners are seeing that savings can be substantial providing great ROI’s to the owner.

This same acceptance and use level has not spilled over into the residential hydronic market. Many hydronic installers still don’t use outdoor reset controls, even when the control is integrated into the boiler. Many don’t activate the outdoor reset control or bother to install the outdoor temperature sensor and wiring. They prefer to just set the boiler at one temperature and enable and disable it with a room thermostat through the TT connection.

Scott Boutilier, technical advisor/instructor with Viessmann-BC told me, “For many contractors, if they can get away without using the outdoor reset control they will. Contractors just want to get in and out of jobs quickly, and they don’t want the hassle of running the sensor wire and setting up the control. Even with our boilers that have factory installed outdoor reset controls, many contractors don’t bother to install the outside sensor and just run the boiler at one temperature.”

Like many areas of the HVAC market, margins are always tight and very competitive, and many contractors want to make projects fast and easy. Many don’t want to ever have to return to the job after they are finished the installation. This usually results in a single thermostat, constant temperature boiler, and NO outdoor reset control. For many projects this means that the full potential of a new condensing boiler is not being optimized, and the customer is left with higher fuel bills and sub-optimal comfort levels.

It’s not all doom and gloom though, as everyone I spoke to say the true “wet-heads” are the exception to this trend and have definitely adopted the use of outdoor reset controls. According to Boutilier, “Good hydronic guys have taken the time to learn about outdoor reset technology, understand how it works, and they know how to adjust and fine tune the controls. They know how to make the controls work, can explain the benefits to their customers and they can easily sell the extra cost required to set up and configure the control.”

Unfortunately these hydronic contractors are not the majority. To those who are using them already, keep it up. These simple controls increase appliance efficiency, reduce greenhouse gas emissions, while at the same time make buildings more comfortable. This potent combination seems like a no-brainer to me!

It is time for everyone in the hydronic heating industry to step up and fully utilize this powerful, yet inexpensive, technology. This not only includes hydronic installers, but also regulators who inspect and enforce code and standards. No hydronic space heating system should be installed without one.

Robert Waters is president of Solar Water Services Inc. which provides training, education and support services to the hydronic industry. He has over 30 years experience in hydronic and solar water heating. He can be reached at solwatservices@gmail.com.