I Need This Controller…

May 1, 2014 | By JOHN SIEGENTHALER

Expanding the possibilities for radiant ceilings with a "year round" controller.

There is a range of solutions depending on budgets, zoning preferences and the equipment used for the heating portion of the system. One of the lesser-known possibilities, at least at present, is using a radiant panel as a “heat absorber” for sensible cooling.

LOOKING UP

The term radiant heating makes most people think about warm floors. Although it is certainly true that there are many excellent applications for radiant floor heating, it is not the only type of radiant panel that can deliver comfort.

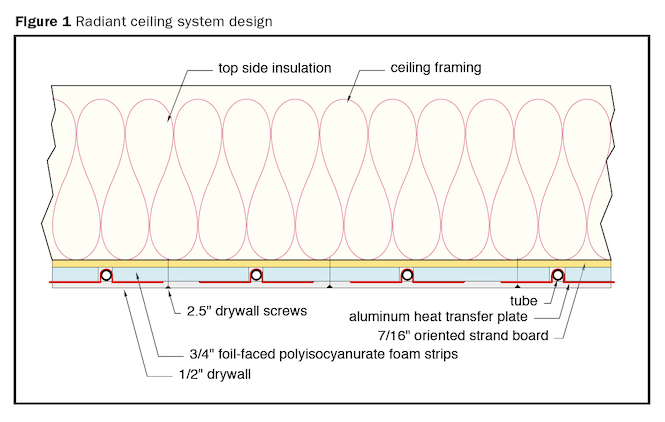

A hydronic radiant ceiling, when properly applied, serves as an excellent low-temperature heat emitter. Some designs, like the panel shown in Figure 1, can deliver a heat flux of 28 Btuh/ft.2 when operating at an average circuit water temperature of 110F. This makes them well suited for use with heat sources such as mod/con boilers, solar thermal collectors and heat pumps.

Figure 1

Its low thermal mass allows it to quickly respond to changes in factors such as internal heat gain and changes in thermostat settings. When properly constructed, this type of panel should last for decades, probably outliving the several heat sources that will supply it.

BEYOND HEATING

Radiant ceilings have another benefit. They are an ideal surface for absorbing heat from living spaces when their surface temperature is maintained slightly lower than the air and objects in those spaces. This is called radiant cooling. I think it has the potential to become a viable (and even highly desirable) option in residential and light commercial building applications.

Radiant ceiling cooling is not as simple as circulating chilled water through tubing embedded in the ceiling. To prevent condensation on or within the panel, the temperature of the chilled water supplied to it must be maintained at about 3F above the current dewpoint temperature of the room.

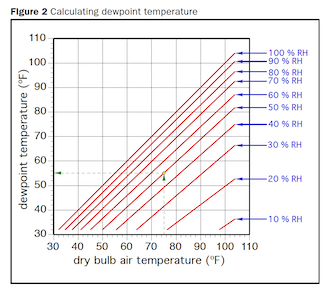

Figure 2.

The dewpoint temperature depends on the dry bulb temperature of the room air and its relative humidity. It can be determined from a graph such as Figure 2, or referenced from a psychometric chart.

A change in either the dry bulb temperature or relative humidity will change the dewpoint temperature and require a change in the chilled water temperature supplied to the radiant ceiling panel.

Furthermore, different areas of a building can have different dewpoint temperatures at the same time. For example, a vestibule in which the exterior door is frequently opened on a hot humid day will likely have a higher dewpoint temperature compared to an interior space with minimal sources of moisture. Buildings with such spaces should be divided into zones and the chilled water temperature to each of those zones needs to be independently controlled.

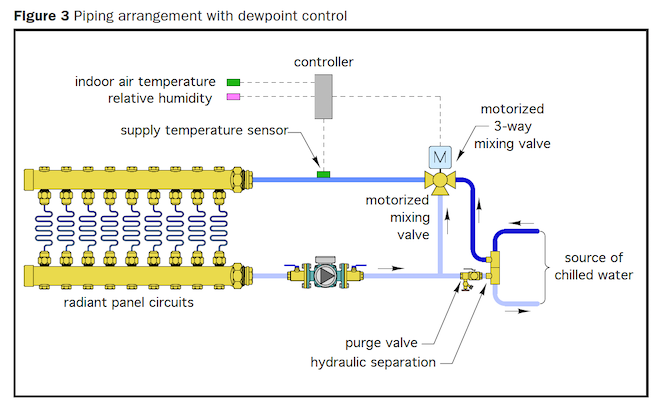

One of the simplest ways to maintain the chilled water temperature supplied to a radiant panel above dewpoint temperature is by using a three-way motorized mixing valve; the same type of valve that would regulate the temperature of warm water supplied to the panel during heating mode. In cooling operation, the valve mixes chilled water, supplied from some source, with slightly warmer water returning from the radiant panel.

The controller operating the three-way valve would continuously sense the dry bulb temperature and relative humidity within a space. It would use this information to determine the current dewpoint temperature. It would then compare this temperature to that of the water being supplied to the panel. Its objective would be to maintain the supply water temperature about 3F above the dewpoint temperature.

Figure 3 shows how this controller would connect with the mixing valve and associated chilled water distribution piping.

Figure 3.

This is the same piping arrangement one might use to control the temperature of warm water supplied to the radiant panel circuits for heating. The only difference is the control logic used to regulate the mixing valve. For cooling, it would be the previously discussed dewpoint control; for heating it would be outdoor reset control where the water temperature supplied to the panel increases as the outdoor temperature decreases.

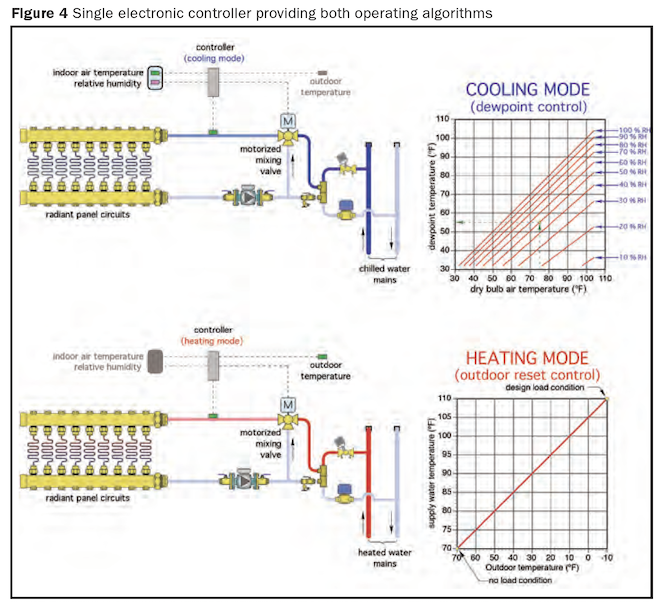

So, wouldn’t it make sense to have a single electronic controller that includes both of these operating algorithms? This would allow the panel that provides excellent thermal comfort in winter to also provide sensible cooling in summer. The concept is shown in Figure 4.

Figure 4.

MORE SMARTS

Because condensation must be avoided, radiant panels can only provide sensible cooling (lowering the air’s dry bulb temperature). Proper design must also address latent cooling (lowering the moisture content of the air). The latent cooling load can only be handled by a device that allows condensation to form within it and then properly disposes of that condensate. Most systems use an air handler for this purpose. The volume of air passing through the air handler is often determined by the ventilation load of the space.

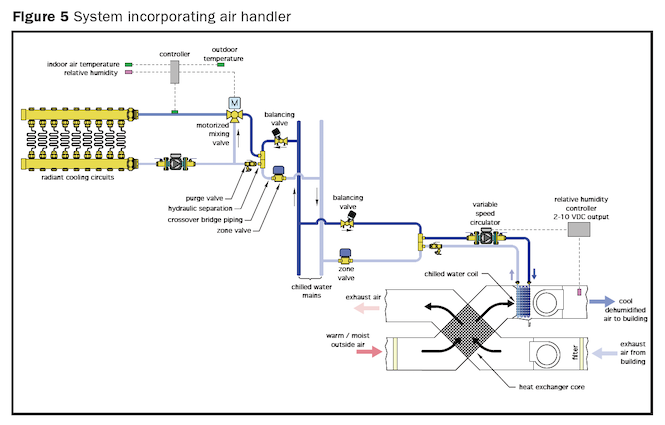

Figure 5 shows the concept for such an air handler. It includes a heat recovery unit that scavenges some of the cooling effect of the exhaust air stream and uses it to precondition the incoming ventilation air. This assembly also includes a multiple tube row chilled water coil that is very effective in dehumidifying the air passing through it. The goal is to dry the air supplied to the space to a condition that allows it to absorb sufficient moisture from the space to maintain a comfortable relative humidity.

Figure 5.

The cooling capacity and rate of moisture removal of the air handler shown in Figure 5 is controlled by the flow rate of chilled water through the coil. In this case, that flow is regulated by a variable speed circulator, which responds to a controller that measures the relative humidity of the supply air stream and compares it to a setpoint value, such as 50%. The controller outputs a signal, such as 2-10 VDC or 4-20 milliamp, which is compatible with the speed controller driving the circulator. When the relative humidity starts to rise above setpoint, the circulator speeds up to increase the capacity of the coil and vice versa.

The air handler system could also be used for ventilation in winter. In cold climates, the circuit through the cooling coil, which could be used to warm incoming ventilation air in winter, would need to be protected by antifreeze.

THE CHICKEN OR THE EGG?

I would love to see some manufacturers offer this combination of functionality (dewpoint and relative humidity control in summer, along with outdoor reset and ventilation air warming in winter) into a simple, stand-alone, “plug and play” controller. I believe having such a controller would enable those who already install radiant heating systems to easily expand into radiant cooling. It is really the only piece missing from the “puzzle” at present.

One long-standing criticism of residential hydronics has been its perceived inability to provide cooling. Here is an opportunity to help end that perception by offering not only the ability to provide cooling, but to do it using state-of-the-art methods that improve comfort, leverage modern devices (such as heat pumps), and significantly reduce the distribution energy required to cool the building. It is also a great way

to merge the best attributes of modern hydronics technology with air-side subsystems for ventilation and latent cooling.

So, for the manufacturers reading this, please consider building this controller. It is an opportunity to deliver a truly unique product – one that could significantly expand the possibilities of modern hydronics technology. <>

John Siegenthaler, P.E., has over 34 years experience in designing modern hydronic heating systems. He is a mechanical engineering graduate of Rensselaer Polytechnic Institute and an associate professor emeritus of engineering technology at Mohawk Valley Community College in Utica, NY.