“Pay for what you use” heat metering technology gains traction

March 7, 2019 | By John Siegenthaler

Buildings such as apartments and condominiums are home to families with different comfort preferences or attitudes on energy use. Similarly, many commercial buildings are divided into spaces where tenants have different temperature requirements or usage schedules.

Buildings such as apartments and condominiums are home to families with different comfort preferences or attitudes on energy use. Similarly, many commercial buildings are divided into spaces where tenants have different temperature requirements or usage schedules.

In some buildings, the thermal energy required to heat or cool each adjoining space is supplied by the building owner at a fixed monthly cost, irrespective of usage. In other cases each space is equipped with its own heating and cooling system, along with the associated meters for electrical and natural gas usage. The cost of heating and cooling is paid directly to a utility by the owner or tenant. Those that use their systems conservatively enjoy lower bills and vice versa. It is a “pay for what you use” concept.

DRAWBACKS

Buildings where each divided space has its own self-contained mechanical system are more equitable from an energy usage standpoint, especially for spaces where thermostat settings are lower, or occupants are not using the space for extended periods due to vacations, frequent travel, and so on. Still, there are several reasons why use of individual mechanical systems is not the best technical or economic option for such buildings.

One common disadvantage of individual heating systems is that each building space will be assessed a monthly basic service charge for the natural gas meter.

Another drawback is a very limited selection for combustion-type heat sources intended for small spaces with low design heating loads. This often leads to use of heat sources that are excessively oversized for the load. The result will be short cycling, reducing service life and lowered efficiency.

Each combustion-type mechanical system also requires its own fuel supply and venting system. This requires gas distribution piping throughout the building and several penetrations of the building envelope for combustion air and exhaust piping. If those penetrations are through the roof, the likelihood of future maintenance to prevent leaks increases.

Separate mechanical systems also take up floor or wall space within each unit. This decreases useable living space or space that would otherwise be available for commercial purposes.

Yet another drawback is access and scheduling for service. Depending on the equipment used and what has to be done, servicing may cause odours, noise, spillage, restrictions on use of space, or other inconveniences.

THINK DIFFERENTLY

An alternative to this business-as-usual of individual mechanical systems in each building unit is to centralize heating and cooling production and combine it with a distribution system that carries heated or chilled water to each unit.

This is hardly a new concept. Central heating and cooling plants have been used in many North American buildings for decades. But until recently most of these systems lacked the ability to accurately measure the thermal energy usage of each space served by the central system. Without such measurements, it is not possible to accurately know where all the heating or cooling energy goes and to follow up with “pay for what you use” invoices.

That situation is changing in North America. Modern hardware for accurately measuring the thermal energy transferred from a central plant to each building space is now available. It is called “heat metering” and presents a growing opportunity for those involved with hydronic heating or cooling systems.

Heat metering, which is extensively used in Europe, requires accurate and continuous measurement of the fluid flow rate passing through each building space, along with the temperature change of the fluid as it passes through the heat emitters or cooling terminal units in that space.

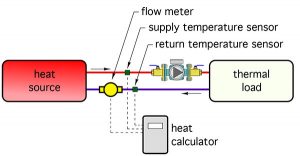

Figure 1 shows the basic concept for how this is done using an electronic flow meter and precision temperature sensors located between a heat source and a load. The electronics needed for calculating heat transfer rate and total heat transferred are contained in the heat calculator unit . The two temperature sensors are supplied as a matched pair and with a specific length of cable attached to both the sensor element and the meter body. The electrical resistance of these cables is accounted for in the meter’s calibration. These cables should never be cut, spliced, or detached from the meter. Any extra length of sensor cable supplied with the meter should be neatly coiled, secured with zip ties and mounted where it will not be disturbed.

Several types of flow meters are used for heat metering, including turbine, vortex, electromagnetic, and ultrasonic. They all have their advantages and limitations. In general, a heat metering system is supplied from its manufacturer as a fully matched group of components including the flow meter, temperature sensors, heat calculator unit, and even some fine stainless steel cable with lead seals. The latter are used to discourage tampering with any hardware that could affect the meter’s reading. Once the seals are set, breaking or tampering with them could have serious legal consequences, depending on the specific agreement between the energy provider and the clients of the system.

Most heat meters are configured, by default, to operate based on the assumption that the system fluid is 100 per cent water. The firmware within the meter contains code that accurately calculates the density and specific heat of water, and uses these temperature-dependent fluid properties to maintain accurate calculations for rate of heat transfer and total heat transferred over time. However, not every hydronic system is filled with 100 per cent water. One example would be solar thermal system operating with a 40 per cent solution of propylene glycol. The density and specific heat of glycol-based antifreeze solutions depends on temperature, as well as the glycol concentration. Fortunately, most modern heat metering systems can be configured to base their internal calculations on the type and concentration of glycol-based antifreeze being used.

SATELLITE STATIONS

Modern heat metering eliminates the previously described limitations of individual mechanical systems in each building space, while also allowing the “pay for what you use” approach.

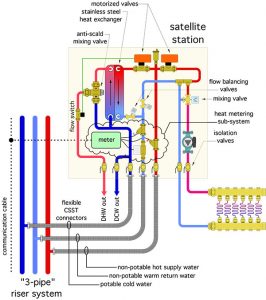

Heat metering is an ideal complement to a centralized multiple boiler system that provides heat for space heating and domestic hot water in multi-occupancy buildings. Hot water from the central boiler system is circulated through mains piping that connects to a “satellite station” in each building unit.

One possible satellite station configuration is shown in Figure 2.

Satellite stations provide the piping and controls needed to regulate space heating to individual preferences. Some also provide prioritized “on demand” domestic hot water through use of a stainless steel brazed plate heat exchanger. Hot (non-potable) water from the building mains passes through the heat exchanger whenever a flow switch in the satellite unit detects a demand for hot water of 0.6 gallons per minute or higher. This operating mode takes temporary precedence over space heating. It stops as soon as the demand for DHW ends. This eliminates the need for a domestic hot water storage tank and its associated standby heat loss. It also eliminates the need for hot domestic water piping and an associated recirculation system within the building. What would otherwise have to be a five-pipe system throughout the building is reduced to a three-pipe system.

GREATER OUTREACH

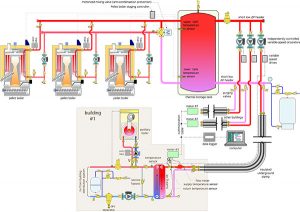

Heat metering is also ideal for district heating applications, where heat and in some cases chilled water, is supplied to each of several buildings from a central plant system. Figure 3 shows the concept of such a heating system where the central heating plant consists of three staged pellet boilers.

The pellet boilers are staged on and off to maintain the thermal storage tank within a specific temperature range. Hot water from the tank is routed by a variable speed circulator through underground insulated piping to a plate and frame heat exchanger in each “client” building. These isolation heat exchangers prevent any cross flow between the central system and the balance of system within the building.

Any leaks or other service issues within one building are not going to impact central heat delivery to the remaining clients. Each client system is also shown with an auxiliary boiler and valving that could sustain the building if there is a service issue with the district system.

PLAYING BY THE RULES

In the U.S., an ASTM standard titled Standard Specification for Heat Meter Instrumentation (ASTM E3137/E3137M-17) was issued in February 2018. It covers the accuracy requirements for several categories of heat-metering equipment. This standard was developed over several years. It refers to several previous heat-metering standards, such as EN1434, which is extensively recognized in Europe. This new standard is expected to be frequently cited by engineers specifying heat metering systems.

In Canada, the government agency Measurement Canada is currently conducting a pilot program to evaluate different types of heat meters in several categories depending on flow capacity (see HPAC February 2019, MH10). The eventual goal, expected to be in place by January 1, 2021, is a listing of approved meters in each category. Heat meters installed prior to the eventual requirement for an approved meter can remain in service until 2026, after which they must be replaced with an approved meter.

PAY ATTENTION

Heat metering represents a significant and broad emerging market in North America. It is a niche that is ideally suited to those working with hydronic heating and cooling systems. It is a technology that provides performance verification, assists in diagnosing system problems, promotes energy conservation and allows equitable sharing of energy costs. This article is but an overview of what is possible. If you are involved with hydronics you need to follow this developing market. <>

John Siegenthaler, P.E., is a mechanical engineering graduate of Rensselaer Polytechnic Institute and a licensed professional engineer. He has over 35 years experience in designing modern hydronic heating systems. Siegenthaler’s latest book is Heating with Renewable Energy (see www.hydronicpros.com for more information).

John Siegenthaler, P.E., is a mechanical engineering graduate of Rensselaer Polytechnic Institute and a licensed professional engineer. He has over 35 years experience in designing modern hydronic heating systems. Siegenthaler’s latest book is Heating with Renewable Energy (see www.hydronicpros.com for more information).