Solar Photovoltaic System Basics

June 19, 2020 | By Rob Waters

What the mechanical industry needs to know about this growing industry.

Housing construction in Canada is being pushed greener all the time. In a past HPAC article I discussed some of the green building code trends that are coming, and how they will affect the mechanical industry (Code Green, HPAC Feb 2017).

Upcoming changes to federal and provincial building codes are going to continue this evolution to more energy efficient buildings. The ultimate goal of most governments is to have building codes that will require Net Zero Energy Ready homes by approximately 2035, with the BC Energy Step Code being a prime example.

For a home to get to a full Net Zero Energy level, where the annual energy consumption of the building is zero, there are two basic requirements that must be met. First, the building must be constructed to reduce the energy consumption substantially by increasing the insulation levels in exterior walls, ceilings and windows, and making buildings very air tight. These construction enhancements, along with the use of low energy lighting and appliances, will reduce the energy load of a Net Zero Energy Ready home by approximately 70% compared to a home built to today’s 2015 NBC 9.36 building code standard.

The second part of getting to full Net Zero Energy is to install an on-site solar photovoltaic (PV) energy system that will produce enough annual energy to offset the energy that the house consumes. When both of these parameters are in place the house will be truly Net Zero Energy.

Currently most mechanical contractors are not very familiar with solar PV systems, but it is most likely time for that to change.

With Net Zero Energy homes becoming more and more common, and the push towards electrification of home heating and cooling systems, solar PV systems are going to become much more mainstream.

These systems have typically fallen into the domain of specialty solar companies, and until recently have been so expensive that only a very small market has developed.

Solar PV prices have dropped dramatically in the last 15 years, to the point where the cost of generating solar electricity has resulted in grid-connected solar PV systems approaching grid parity throughout Canada.

In this article I hope to introduce contractors to the basic construction requirements of installing an on-site PV system, the main components of the PV system, as well as how much energy the PV system will be expected to produce.

The only difference between a Net Zero Energy (NZE) home and a Net Zero Energy Ready (NZEr) home is whether or not the on-site solar PV system has been installed. Most builders who are currently building to this standard are building NZEr homes, and leaving it up to the homeowner to decide if they want to install the solar PV or not.

Regardless, the home can still be built to a standard that easily allows for the solar PV to be integrated at the time of construction, or any time in the future.

To ensure that everything is done correctly for the solar installation, Natural Resources Canada (NRCan) has developed a set of “Photovoltaic Ready Guidelines, Ver 2.0” for builders.

These guidelines can be downloaded from the NRCan website, and they describe the design considerations and modifications that builders can make to a home’s construction to prepare for the installation of a future solar PV system.

The design considerations and modifications include the following elements:

- the roof requirements

- the PV and utility connection conduit installation and termination

- mechanical room wall space

- electrical panel rating

- and breaker slot and network communications.

Making a home “solar PV ready” is relatively simple and inexpensive to implement when it is done at the time of construction, and will lead to significant savings in installation costs when the solar PV is installed at a later date.

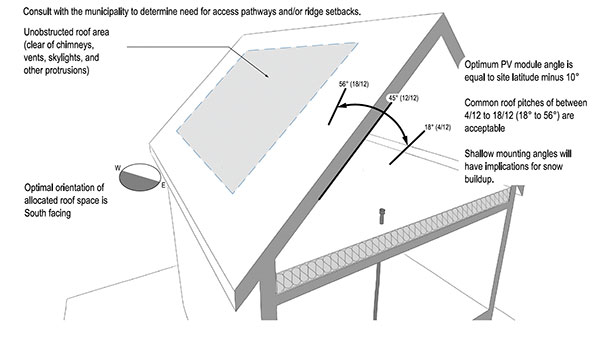

Figure 1. Roof space, orientation and mounting angle of solar PV panel. (NRCan)

The first item that Solar PV Ready Guidelines focus on are the roof requirements (see fig 1). The slope and orientation of the roof are site-specific conditions that have a huge influence on the performance of a solar PV system and how much electricity it will generate.

The size of roof space that is available dictates how many PV modules can be installed, and of course any shading on the PV modules must be avoided.

The ideal situation is to have a roof surface that is oriented directly south, with a roof slope of 10-degrees less than the site latitude, and no shading. This ideal situation is not always possible however, and it is okay to deviate a little on the slope and orientation as this will result in only a minor drop-off in system performance.

It is best to keep the roof orientation within 45-degrees east or west of direct south, and the roof slope should be between 18- to 56-degrees (corresponds to a pitch of 4/12 to 18/12).

Note that PV panels on low roof slopes can have issues with snow accumulation, so low slopes should be avoided in high snow loads areas. The available roof area being allocated for PV modules must be unobstructed by chimneys, roof vents, skylights, gables, and must be large enough to accommodate the required amount of PV panels.

A PV system sized to provide an energy output sufficient to offset all or most of the annual energy consumption of a NZEr home will require approximately 30 PV modules, requiring an area of approximately 500+ sq. ft.

Builders must also ensure the roof structure not only meets all applicable building code requirements, but will also support the additional dead load and wind and snow loads associated with common photovoltaic energy systems.

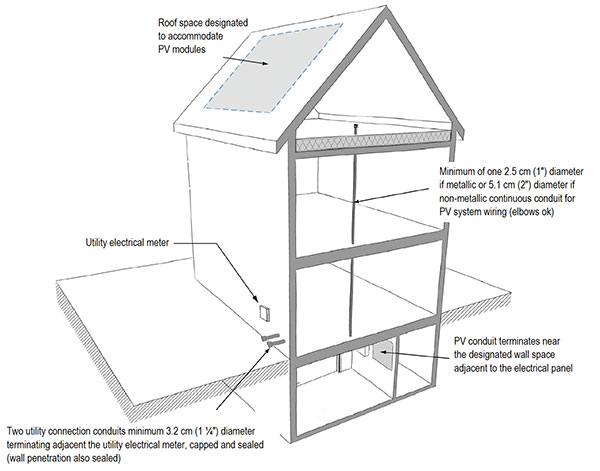

The next building consideration is to allow for easy installation of all the necessary PV wiring. There are two paths required, one from the roof location to the electrical panel location, and another from the electrical panel to the outside utility electrical meter location (see fig 2).

Fig. 2. Solar PV conduit and utility conduit specification.

For the roof wiring, the builder will need to install a PV conduit constructed of metallic conduit of at least 1-in. nominal diameter, or non-metallic conduit of at least 2-in. nominal diameter.

This conduit must be installed entirely inside the building envelope and will extend into an accessible area of the attic close to the PV roof, and down into the electrical panel area. Bends are permitted but should be limited where possible to make the future pulling of wires easier.

For the connection of the PV system to the outdoor utility meter, two utility connection conduits of at least 1-1/4-in. nominal diameter rigid PVC conduit should be installed. These two connections allow for the PV system to be connected to the electrical grid for net-metering, and to allow for a PV disconnect switch to be located outside the building.

This PV disconnect switch is required to protect utility workers that may be working in the local area. When the builder is not installing the PV at time of construction all of these conduits must have their ends capped and sealed.

Wall space must be allocated in the electrical room, adjacent to the house’s main electrical panel, for the future installation of a PV system inverter and connection hardware (see fig 4). A recommended space of 36- x 36 in. is suitable, with a minimum clearance 36 in. up from the floor.

Other PV system electrical considerations include ensuring sufficient electrical panel ampere rating (usually 200 A is a good idea) and allowing for network communication wiring for PV inverter communication to the internet.

There is great software available that allows for the PV system to be tracked on-line with terrific graphics and live electrical production data displays.

The NRCan PV Ready Guidelines, v. 2.0 go through many more technical details on the roof, conduit and electrical room requirements, so download a copy for more details.

The main components that make up the solar PV system are: the solar PV panels, roof mounting hardware, wiring/cables, the power inverter and the electrical meters.

Solar PV panels are typically made of 60 or 70 crystalline silicone cells which are electrical devices that can directly convert solar photon energy into electricity. PV panels generate direct current (DC) output. There are several types of modules available with the most common being either mono-crystalline or multi-crystalline. Most modules are available in either 1 x 1.6 m or 1 x 2 m sizes, incorporate a tempered glass cover sheet and an aluminum frame.

The modules are typically about 1.4-in. thick and weigh roughly 40 lbs. The panels are attached directly to the roof structure using a variety of aluminum frame rack systems, which connect to the roof joists or decking and keep the panels about 2 to 3-in. off the roof surface.

The solar inverter, or PV inverter, is an essential part of any PV system. It receives all of the variable DC output of the solar panels and converts it into an alternating current (AC) that can be utilized on-site by local household loads, or fed into a commercial electrical grid.

There are different types of inverters used depending on whether the system is a grid connected system, a standalone system with batteries, or a hybrid.

As noted, the total cost of installing solar PV has plummeted in the past 15 years as the PV industry has gone through massive worldwide growth. In 2005 installed residential system prices were in the range of $10/W, where now systems are being installed as low as $2.75/W. Large scale commercial systems are being installed in the southern U.S. for less than $0.90/W.

When a residential house has been built to PV Ready Guidelines, the installed cost of the solar PV will be even less due to the reduction in labour and materials.

Storing the PV energy in batteries is an option, but today PV systems are most commonly grid-connected.

The energy consumption load of a typical household usually does not match the times when PV panels are generating most of their energy. When the system is grid connected it allows any excess energy to be fed into the electrical grid.

Net-metering is a billing mechanism that credits the PV system owner for the electricity they add to the grid. The bi-directional electricity meter will run backwards when PV energy is being exported to the grid. This exported energy provides a credit against the electricity that is consumed at night or on cloudy days when the home’s electricity use exceeds the system’s output.

If the home is net-metered, customers are only billed for their “net” energy use. There are currently net-metering programs available in most provinces in Canada to encourage the installation of solar PV systems.

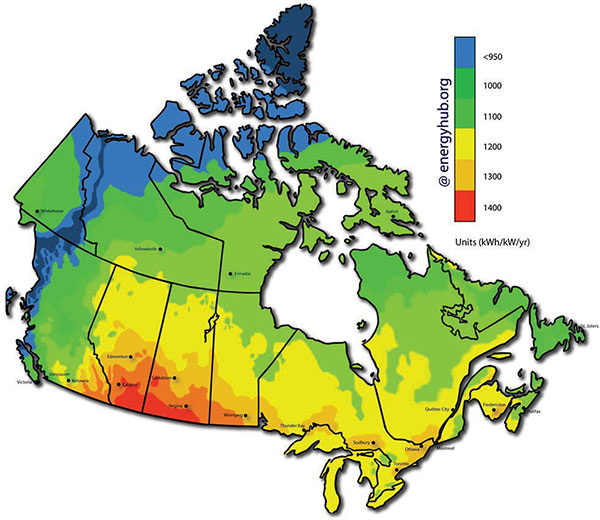

The total annual amount of energy produced by a solar PV system is influenced by many factors such as the geographic location, the local site conditions and the size of the solar PV array.

The global solar radiation that any location receives is based on the geographic location of the home. All areas of Canada receive differing amounts of annual radiation with the highest amounts in the southern prairie regions of Saskatchewan and Alberta. There are solar PV radiation maps available from various sources that show exactly how much PV energy production to expect in your area (see fig 4).

Fig. 4. Solar PV system expected energy production in Canada. (source: Energyhub.org)

Solar PV systems are rated by kW, with a 1 kW system consisting of about 5 PV panels requiring a roof area of 80-90 sq. ft. Depending where you are in Canada a 1 kW system can produce 1,000 – 1,400 kWh of electricity per year.

A home constructed to NZE standards will typically require an 8.4 – 9.6 kW PV system with 30 PV modules to produce 100% of its annual energy.

The push towards Net Zero Homes, and the electrification of space and water heating systems are emerging trends that the mechanical industry is facing. NZEr homes will have dramatically reduced space heating and cooling loads requiring very small-sized heating and cooling equipment.

Climate change initiatives will continue to push for electrification of the heating industry and promote the installation of renewable energy systems. Understanding the role of solar PV systems will be an important part of navigating this emerging green building industry. <>

Robert Waters provides training, education and support services to the hydronic industry. He has over 35-years’ experience in hydronic heating and solar water heating. He can be reached at

Robert Waters provides training, education and support services to the hydronic industry. He has over 35-years’ experience in hydronic heating and solar water heating. He can be reached at